CLEAN

ENVIRONMENT

CONTINUOUS EFFORTS

FOR A CLEANER ENVIRONMENT

R&D

- Clean Environment

- R&D

Shinsung E&G presents innovative technologies and implements optimal solutions through advanced R&D activities.

Our technology research institute has personnel capable of conducting simulations of electronic devices as well as structural and airflow simulations. We develop products optimized for customer needs through experiments and simulations on products under development. We will practice technological innovation through research and development based on our expertise in keeping with the great changes in future industries.

Clean Manufacturing Environment Clean Room

Particle

Particle Smell

Smell Temperature

Temperature Humidity

Humidity

-

01

- High technical level

-

- - Fan and Motor

- - High-integration minimum loss and piping flow design technology

-

02

- Differentiated technology

-

- - Noise and vibration control technology

- - Airflow and structure optimization technology

- - Manufacturing, environmental, and gas analysis technolog

-

03

- Advanced source technology

-

- - Air purification technology

- - Heat exchanger design technology/li>

- - Pollutant gas removal technology

-

04

- Securing reliability

-

- - FAB-oriented environmental analysis

- - Safety assessment for the long-term operation of plants

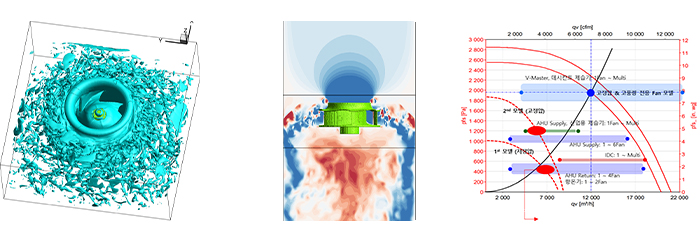

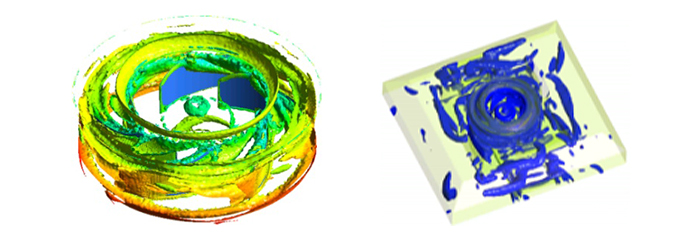

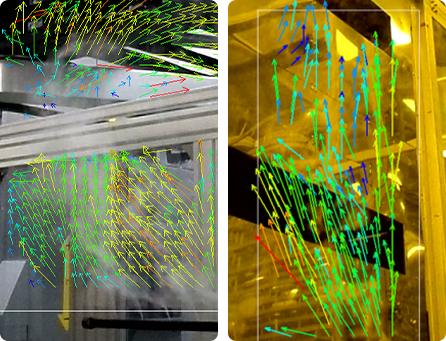

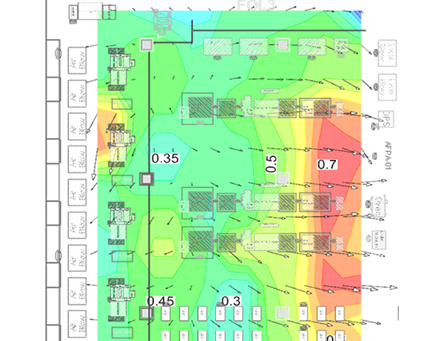

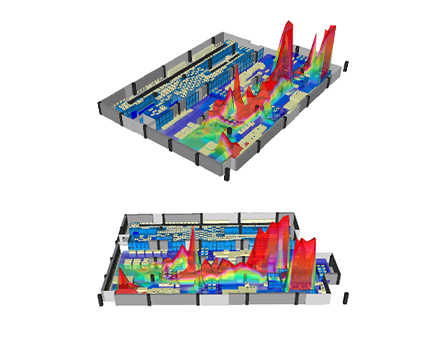

Computational Fluid Dynamics

Computational Fluid Dynamics (CFD)

Measurement of factors affecting contamination such as airflow, temperature, humidity, cleanliness, VOCs, etc. in clean rooms/manufacturing equipment Analysis of problems and derivation of improvement plans through the visualization analysis of the measurement results to identify the problems through the intuitive analysis of the measurement results

-

Air Flow Visualization

-

Air Flow Measurement & Mapping

-

Particle Measurement & Mapping

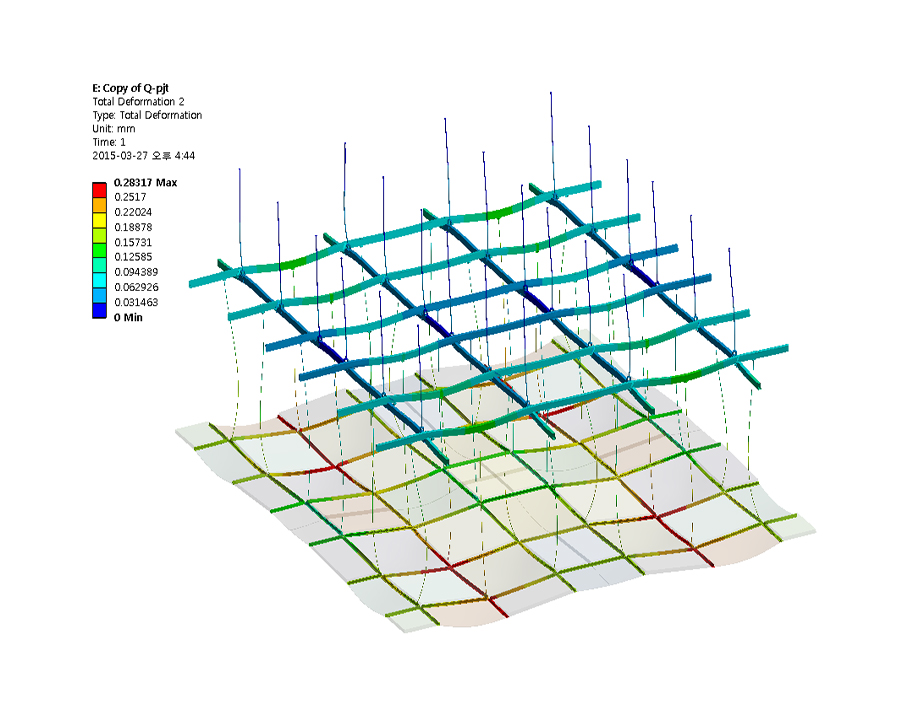

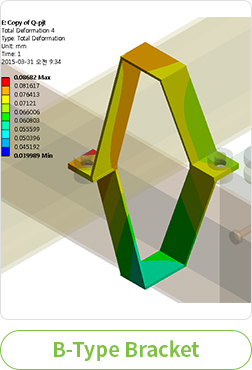

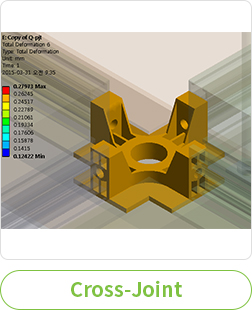

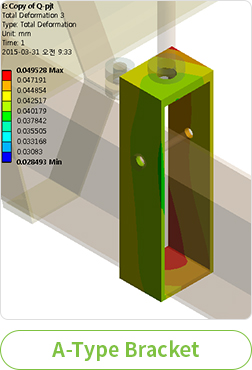

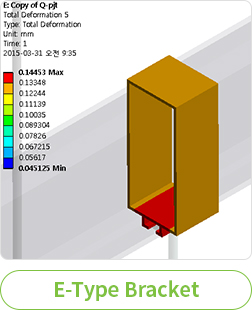

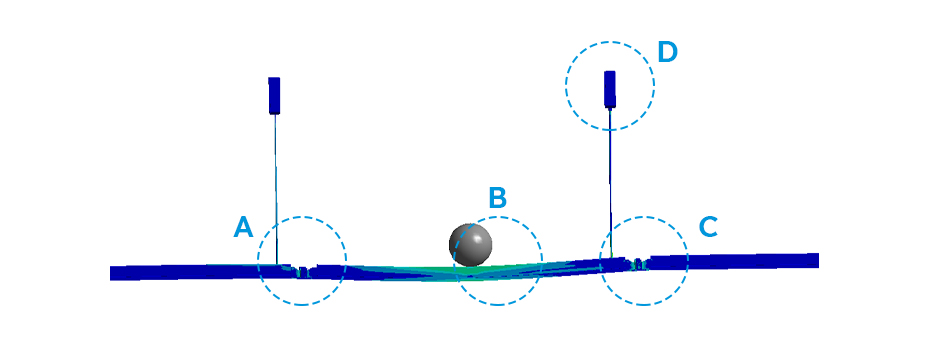

Finite Element Method

Finite Element Method (FEM)

Analysis and improvement of deflection in the ceiling grid system and of each member's safety factor Increase in safety factor and improvement of deflection amount through analysis of structural deflection and strength according to increase in the mini-environment size Structural design to ensure the durability and robustness of the solar power generation system in response to changes in the natural environment by season

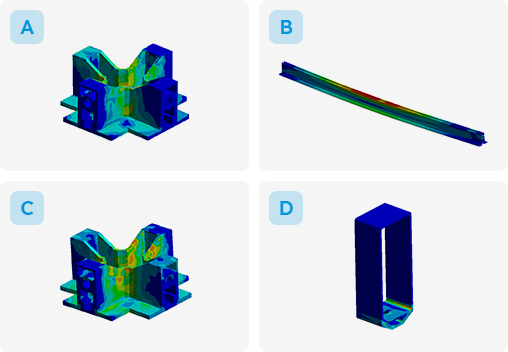

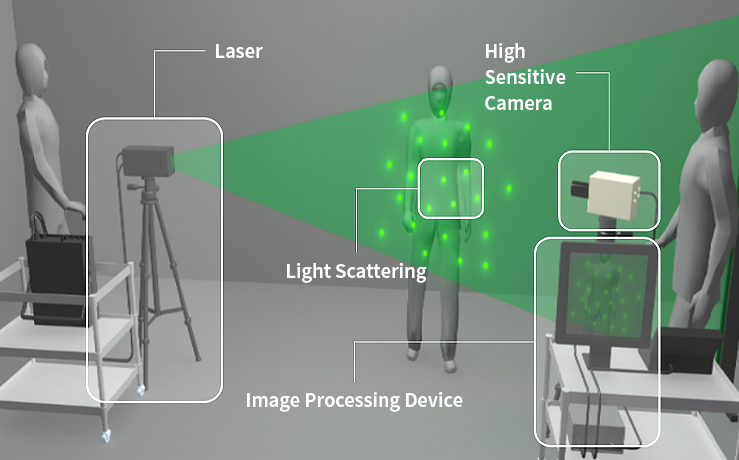

Fine Particle Visualization System

Fine Particle Visualization System (FPVS)

Identifying the causes and intuitively deriving the solutions by visualizing the 0.1um particles (minimum particle size) that may cause defects during production Understanding the generation, movement, and contamination mechanisms of particles by visualizing the particles generated during the actual process

Gas Analysis Technology

Qualitative and quantitative analysis of volatile organic compounds and minute amounts of other pollutants Outgas analysis of materials brought into the clean room Deriving optimal removal solutions by identifying the types of contaminants generated in semiconductor/FPD clean rooms Provision of recycling solutions through air quality assessment

- Analysis items

-

- - Qualitative and quantitative analysis of volatile organic compounds

- - Qualitative and quantitative analysis of solid samples' outgas

- Subject of analysis

-

- - Semiconductors, displays, and other VOCs-generating sites

- Analysis items

-

- - Cations: Li+, NH4+, K+, Ca2+, Mg2+

- - Anions: CH3COO-, HCHO-, F-, Cl-, NO2-, NO3- SO42-

- Subject of analysis

-

- - Semiconductors, displays, and other ionic gas-generating sites

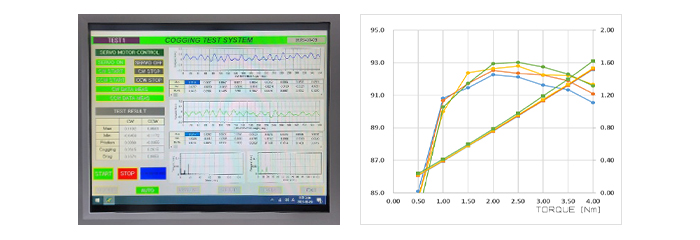

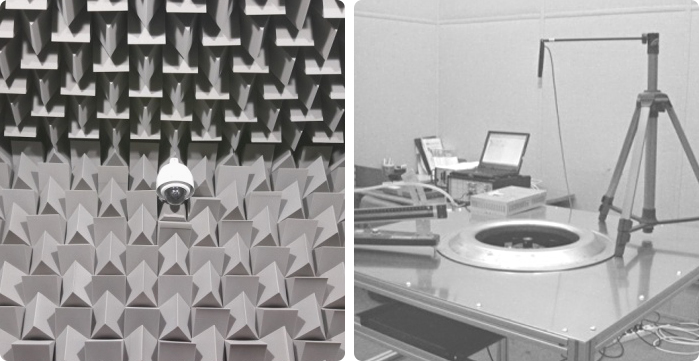

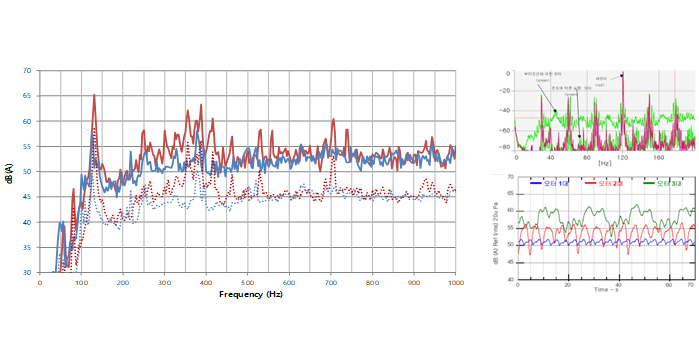

Noise and Vibration Analysis Technology

Provision of ways to measure, analyze, and improve the causes of noise/vibration in our own anechoic room and analysis techniques for predicting the effects of the noise Analysis and improvement of noise in vibration-free equipment / analysis of noise and vibration characteristics in the FAN-MOTOR and their improvements / prediction of synthetic noise by a clean room system

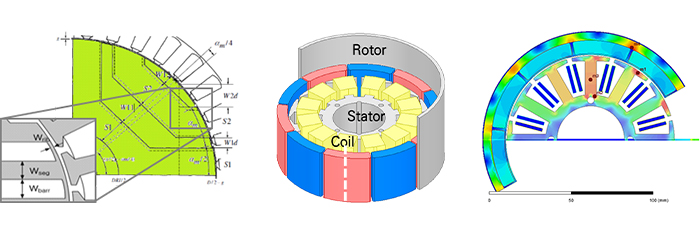

Optimal FAN and BLDC MOTOR Design Technology

The world's best high-efficiency, high-performance FAN design technology Securing the reliability of motors through lightweight and high-efficiency designs and accelerated test evaluation verification