CLEAN

ENVIRONMENT

CONTINUOUS EFFORTS

FOR A CLEANER ENVIRONMENT

Clean Room EPC

- Clean Environment

- Clean Room EPC

Batch construction

Shinsung E&G's

Total Solution for Clean Rooms

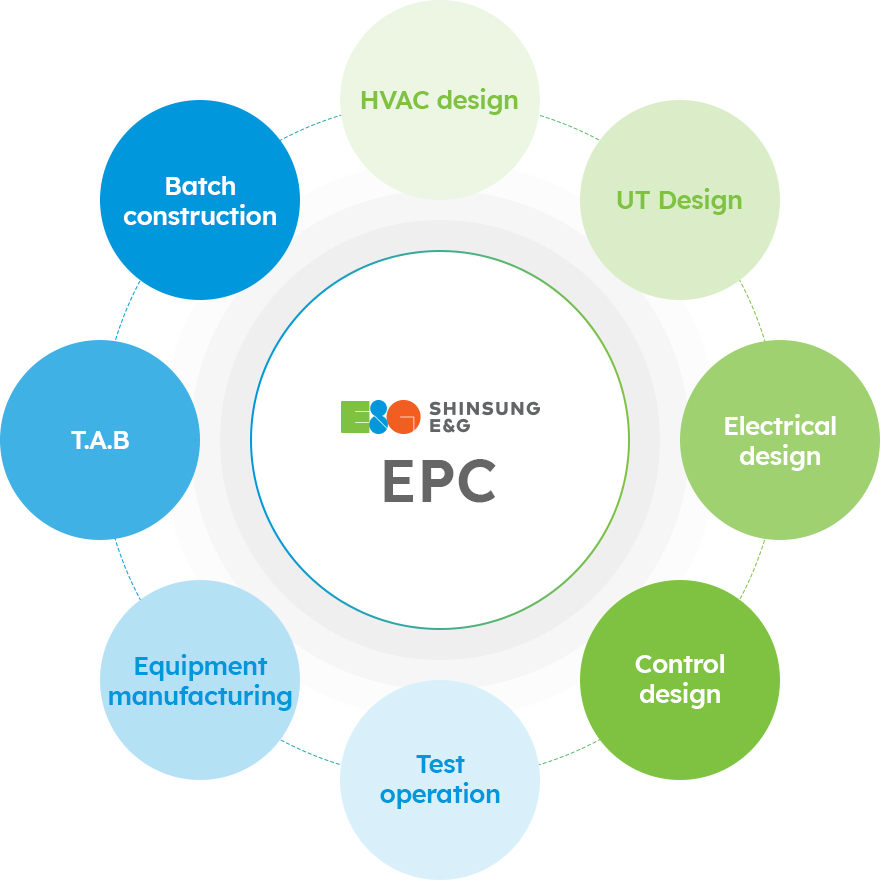

We provide our customers with all total solutions for clean rooms from the construction, expansion, and renovation of factories requiring clean rooms to the planning and designing of processes for clean room facilities excluding construction, heating & cooling facilities for the air conditioning, telecommunication facilities, automatic control facilities, process utility facilities, etc., equipment manufacturing, procurement, construction, test operation, T.A.B, and after-sales service.

EPC : Engineering, Procurement, and Construction

Introduction to EPC

-

HVAC

- Clean room air conditioning system

- Heat source supply system

- System Ceiling, Access Floor, Panel

-

UT

- PCW, DI, UPW, CDA System

- Air pollution prevention facility (Scrubber and AC Tower)

-

ElectricityControl

- Central control system

- Lighting and heat (illuminance simulation)

- Power trunk

-

Construction

- Batch construction

- T.A.B, test operation, and completion cleaning

Process

-

01Receipt of

01Receipt of

data -

02Preparation of

02Preparation of

a proposal -

03Review by

03Review by

client -

04Design

04Design -

05T.A.B

05T.A.B -

06Test

06Test

operation -

07Completion

07Completion

cleaning -

08Construction

08Construction

Design

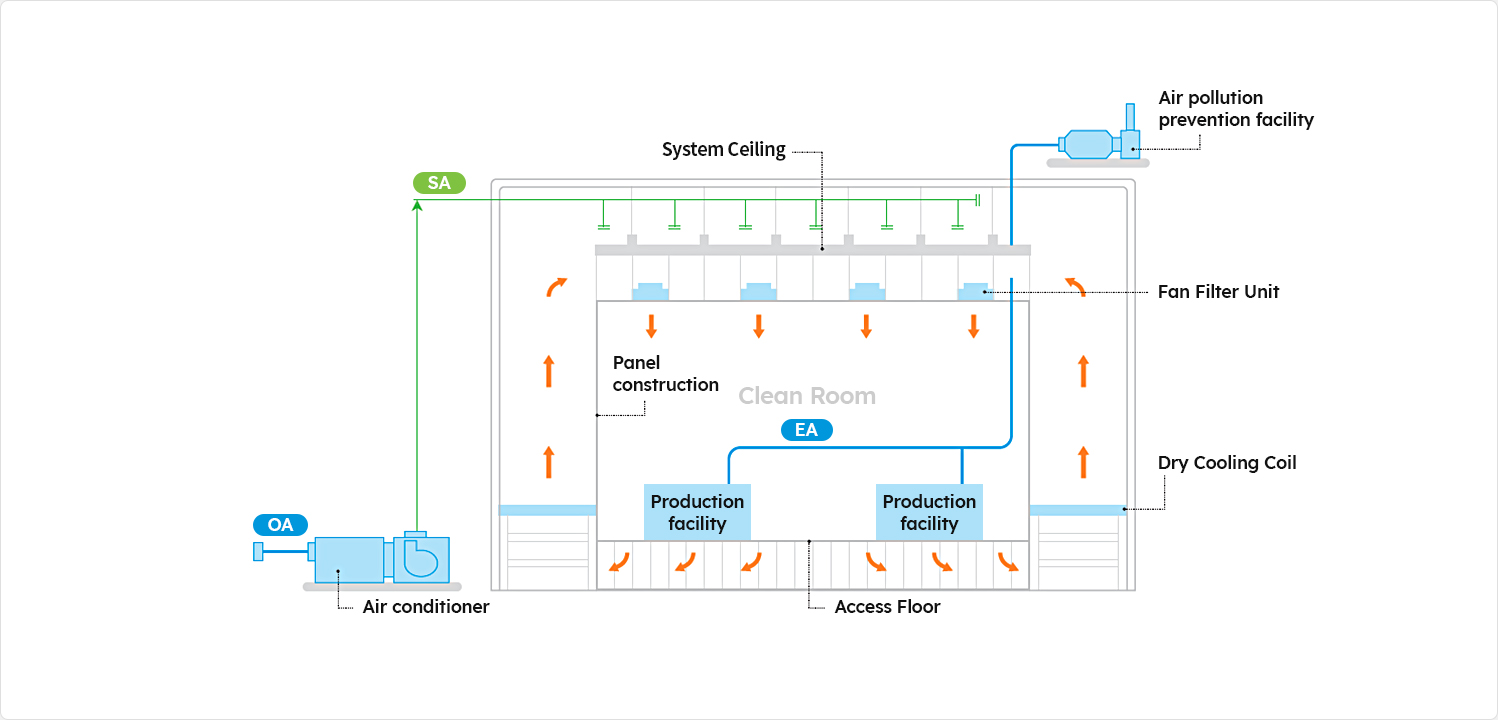

- Industrial Clean Room Design

- It mainly controls fine particles to improve the product yield and controls various environmental conditions such as temperature, humidity, pressure, airflow, noise, and vibration as needed, in addition to cleanliness.

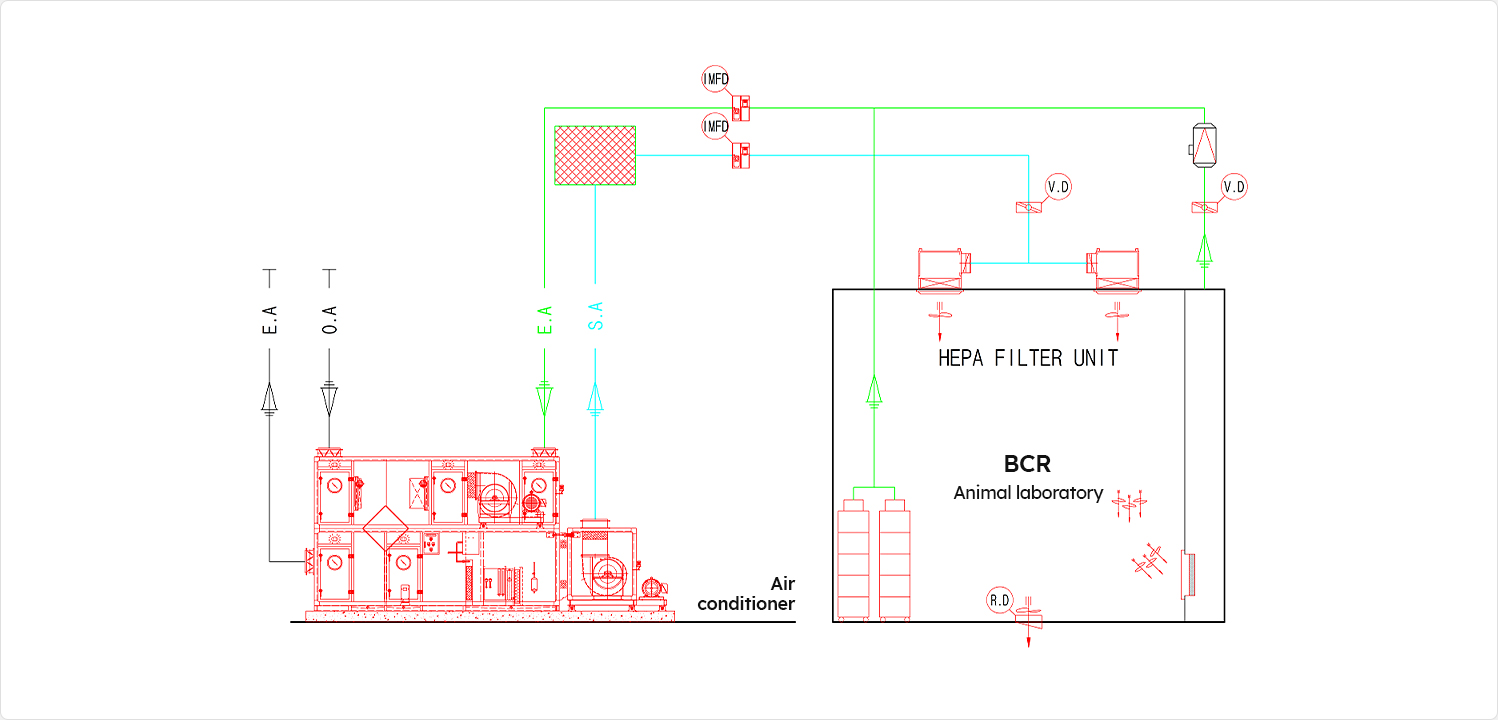

- Bio Clean Room Design

- It is applied to clean spaces where biological contamination is controlled, such as pharmaceutical and medical facilities, clean rooms for cosmetics, etc., and biohazard facilities.

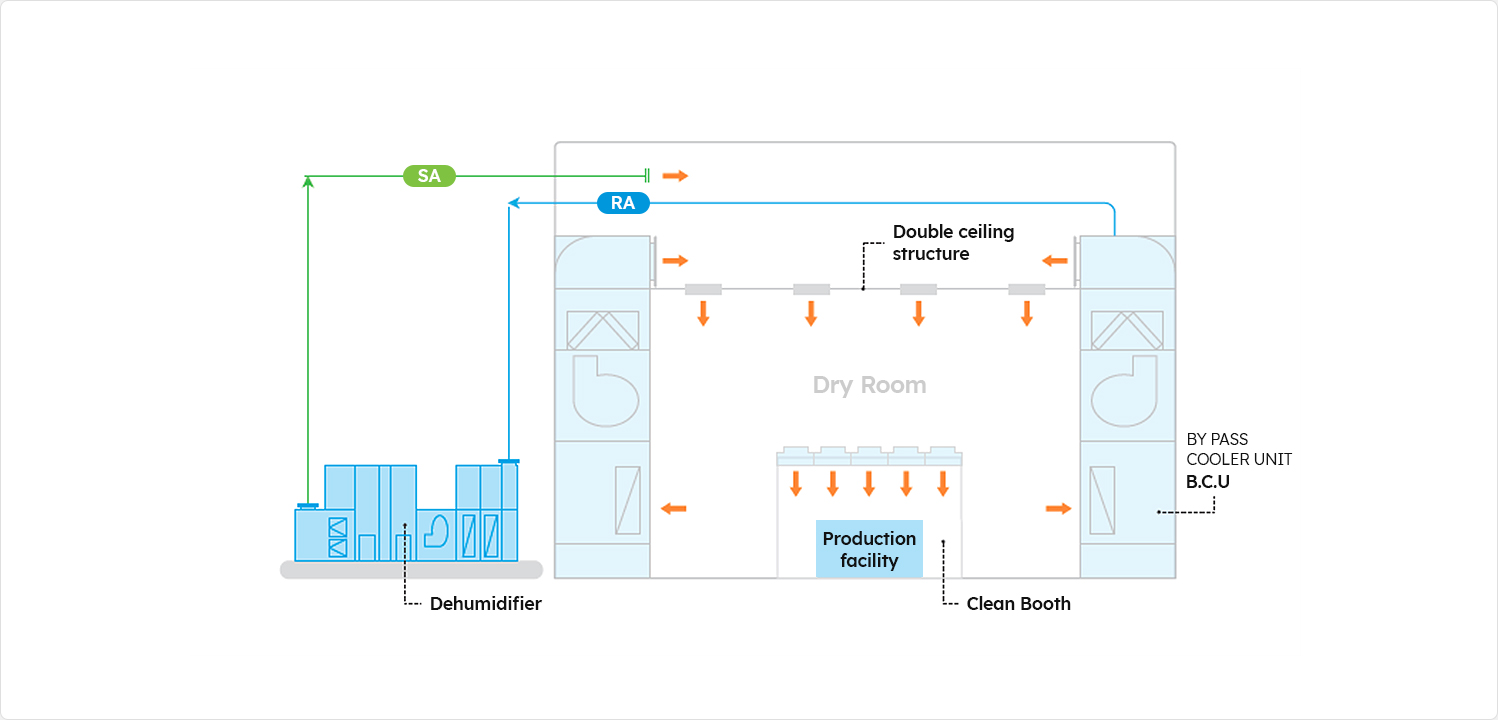

- Dry Room Design

- It is applied to various industries, such as batteries, electrolytes, pharmaceuticals, food, bio, etc., which require low-humidity spaces with a dew point of -10℃ or lower., and it perfectly controls moisture by maintaining a constant temperature and cleanliness to prevent risks of explosion, etc. during the product production and R&D activities.