CLEAN

ENVIRONMENT

CONTINUOUS EFFORTS

FOR A CLEANER ENVIRONMENT

AI Air Solution Center

- Clean Environment

- AI Air Solution Center

The nation's largest intelligent factory leading the AI-based ultra-gap air-conditioning business

The Jeungpyeong business site is the nation's largest air-conditioning equipment assembly facility with an area of 42,909m2 and provides our customers with total system technology solutions optimized for various industries such as domestic and foreign clean industries, including semiconductors, FPD, secondary batteries, ESS, bio, etc., the nation's fostering industries, etc.

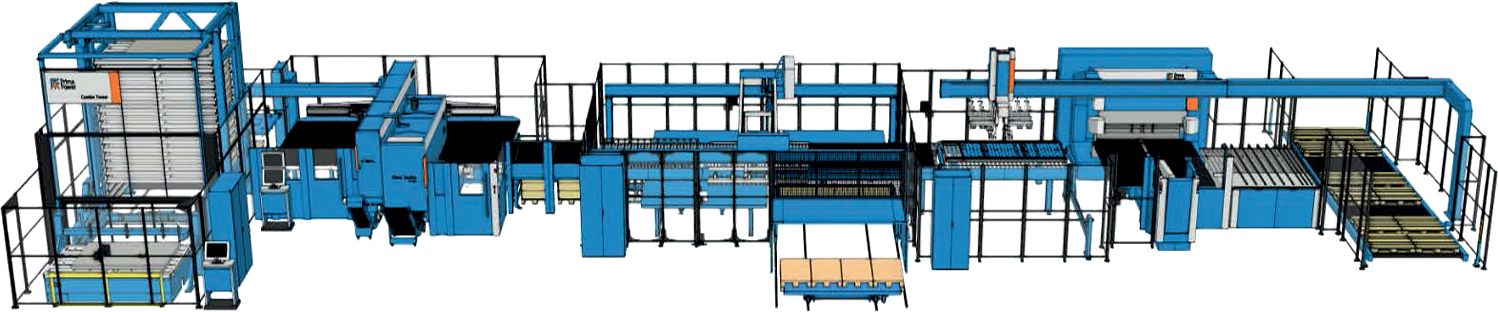

Sheet Metal Processing Line

Full Automation

The automated sheet metal processing line shortens the production period, enables small quantity batch production, prevents manufacturing errors through automatic monitoring, and supports sophisticated manufacturing through the application of the latest digital technology.

-

STEP 01

Warehouse System (Combo Tower 1530)

Warehouse System (Combo Tower 1530)- No replacement time: Suitable for small quantity batch production

- Real-time monitoring of sheet quantity

-

STEP 02

Sorting-Loading Robot (PSR1530/2)

Sorting-Loading Robot (PSR1530/2)- Preventing loading of two sheets and errors in thickness before bending by applying the thickness measurement system (TMS*) of sheets

- Storage of 10 parts in buffer storage

*TMS : Thickness Measurement System -

STEP 03

Punching & Shearing Combination Machine (SG1530 EVO)

Punching & Shearing Combination Machine (SG1530 EVO)- 13% reduction in materials by punching and shearing

- Minimization of noise and surface scratches through the application of a brush plate worktable

- Installation of up to 382 tools on 20 turret stations

-

STEP 04

Automatic Bending Machine (EVe2220 FM)

Automatic Bending Machine (EVe2220 FM)- Control of bending force and position by servo-electric technology

- Application of the automatic tool change (ATC*) system

- Securing 20,000 or more correction bending information with the application of the material database system

*ATC : Automatic Tool Change -

STEP 05

Automatic Unloading and Stacking System (USS*)

Automatic Unloading and Stacking System (USS*)- Automatic stacking of bent products

- Shortening cycle time (C/T*) by product bending during loading and unloading

- Stacking of products with various position programming

*USS : Unloading and Stacking System*C/T : Cycle Time

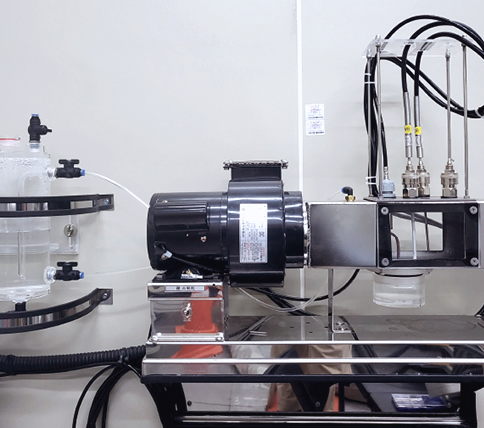

Calorimeter

Definition and Function

-

01Precision test facility that consists of an insulating structure, a precision air-conditioning system (air conditioner, refrigerator, humidifier, etc.), a constant temperature chamber, and control and monitoring units

-

02Changing the temperature and humidity in the chamber in various ways and maintaining them precisely to perform tests according to environmental conditions

-

03Carrying out various performance tests such as operating capacity, electrical characteristics, etc. of products by various heat sources (air-air, air-water, and water-water)

-

04Carrying out reliability tests for air-conditioning and refrigerating products by environment (extreme cold or heat)

Composition

Securing empirical evaluation data through the establishment and operation of our own calorimeter

-

Measurement system

-

Constant temperature and humidity chamber

-

Monitoring system

Internet Data Center

Provision of the optimal air-conditioning service for Internet data centers

-

01Consulting & design

- Power density

- PUE

- Cooling power

- Modified capacity

-

02Construction of infrastructure

- IT space

- Infrastructure space

- Operation space

- Work space

-

03General operation

- Electrical equipment

- Air-conditioning

- Security

- Emergency response

-

01IDC-oriented cooling system

- High performance

- High efficiency

- Miniaturization

-

02Design, construction, and C/S system manpower

- Research manpower

- Construction manpower

- CS

-

03Construction of an integrated network infrastructure

-

04Rapid response

- The nation's largest air-conditioning equipment production facility

- Construction of a systematic system for research, design, manufacturing, etc. (development of customized equipment available)

- AI-based standardization and automated operation process

- Adjacent cooling system suitable for high-density, high-density cloud environments

- Professional C/S organization (real-time response tailored to customers)