CLEAN

ENVIRONMENT

CONTINUOUS EFFORTS

FOR A CLEANER ENVIRONMENT

Dry Room

- Clean Environment

- Dry Room

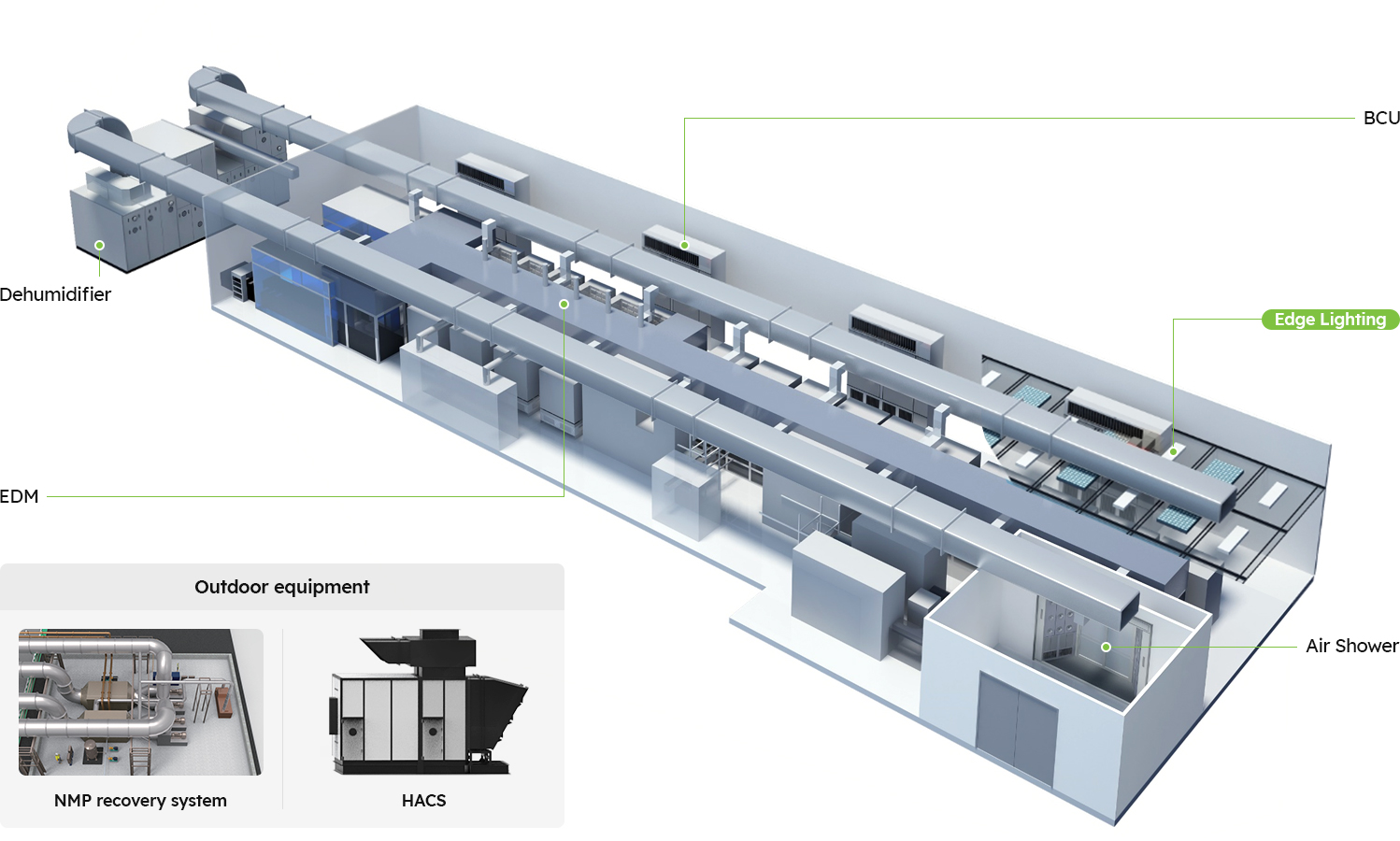

DR, Dry Room

Ultra-low humidity space (-60℃DP)

to produce secondary batteries

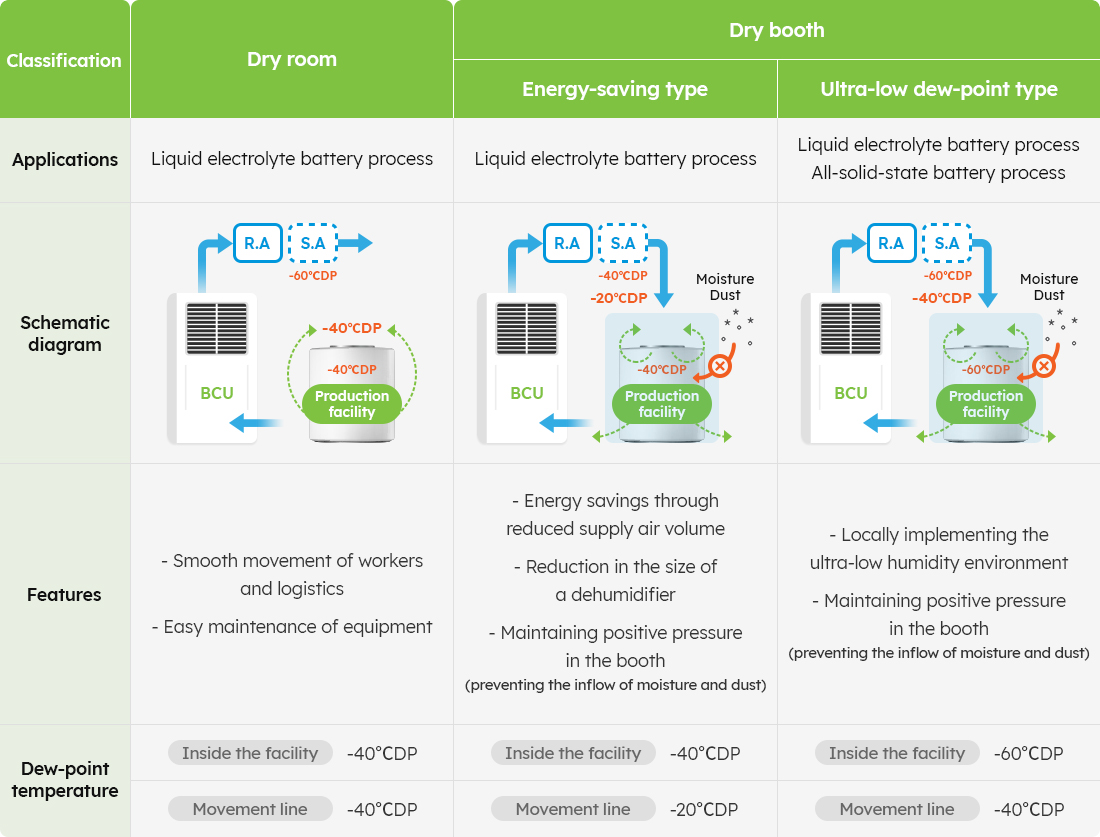

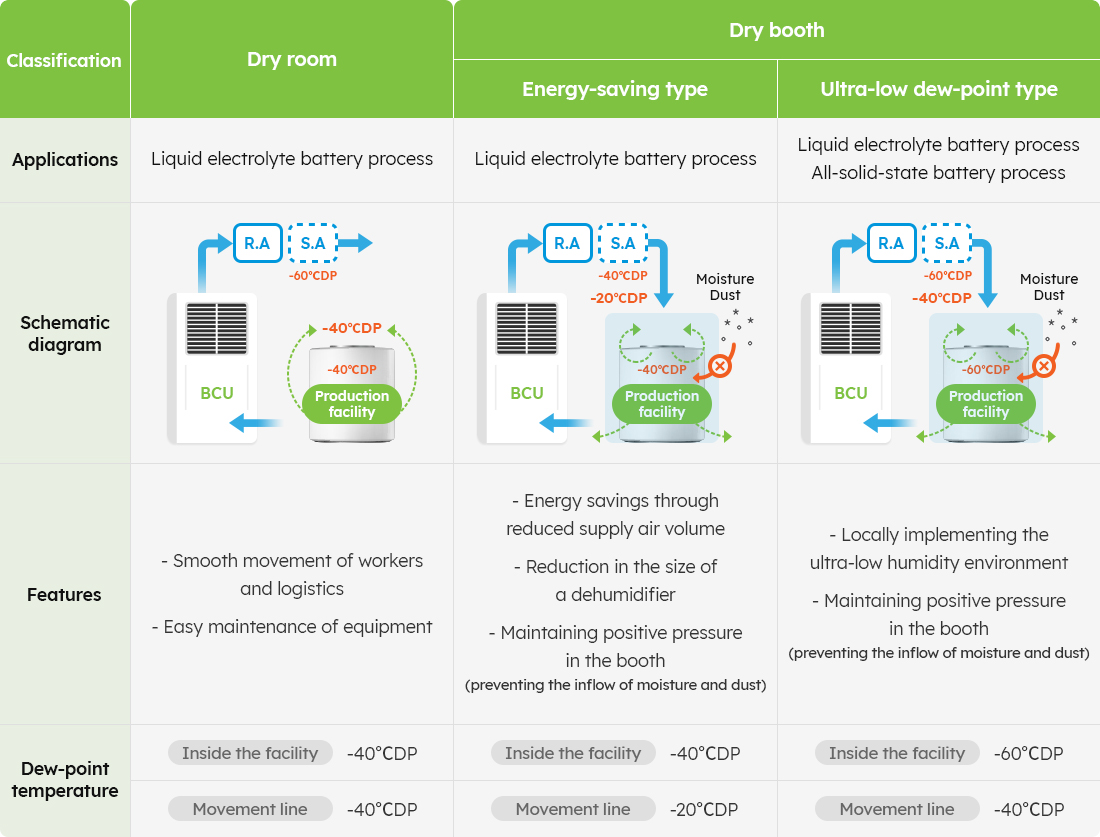

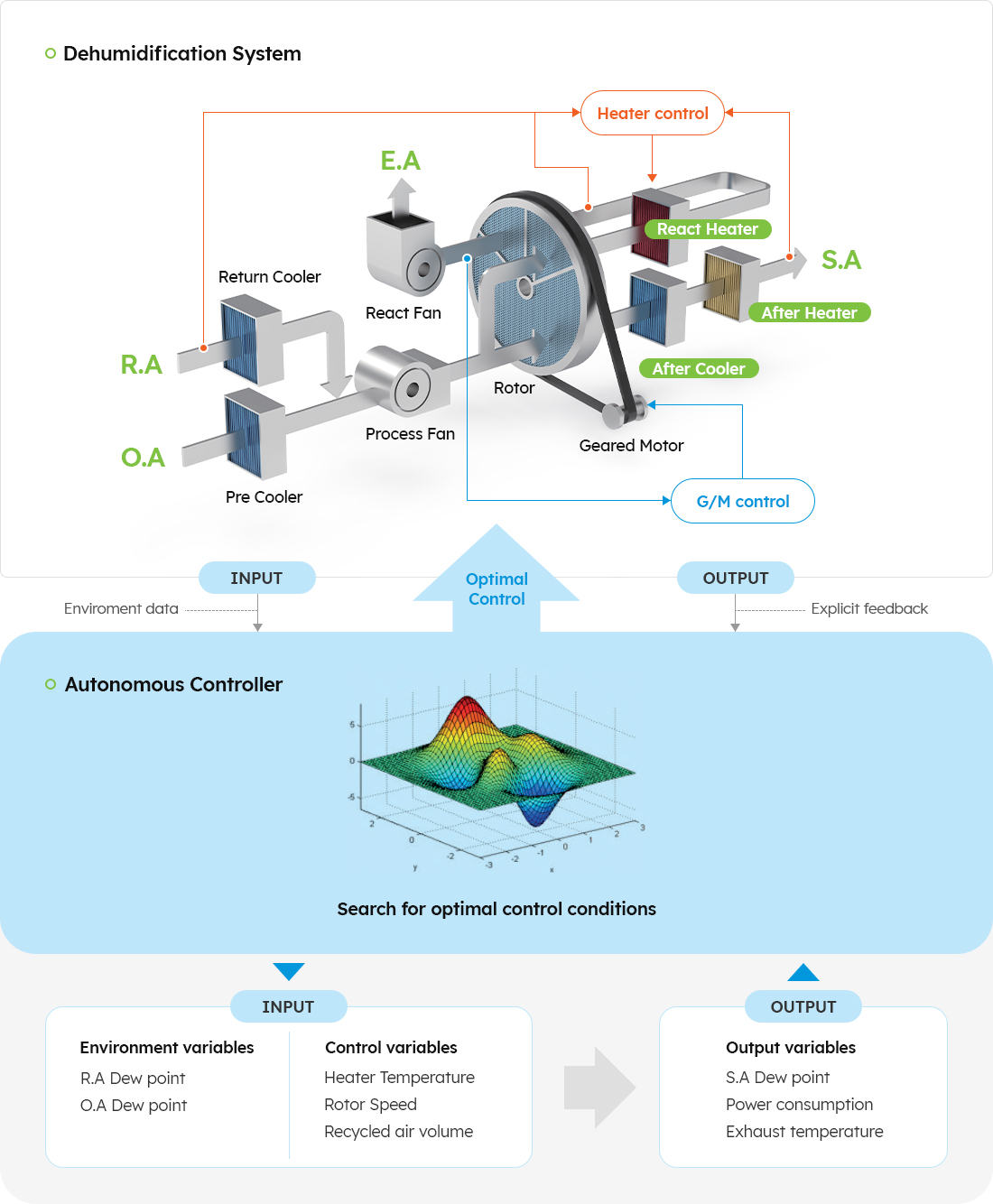

Shinsung E&G provides our customers with a dry room that has an ultra-low humidity environment (-60℃DP) to produce secondary batteries. We have begun developing dry room technology that reduces the operating energy of industrial dehumidifiers through a technical partnership with a company specializing in desicant rotors in 2016. As a result, we have obtained a patent for a dry booth that reduces controlling costs by reducing the amount of air at a low dew point, supplied to the local dehumidification area in the dry room. We are building an optimal environment by controlling humidity perfectly with innovative air control technology, and we are achieving energy efficiency and reduced operating costs through a dry booth. We are continuously conducting technology development to establish an ultra-low humidity environment essential for the production of all-solid-state batteries, and we are actively responding to the increasing global demand for dry rooms by establishing overseas corporations.

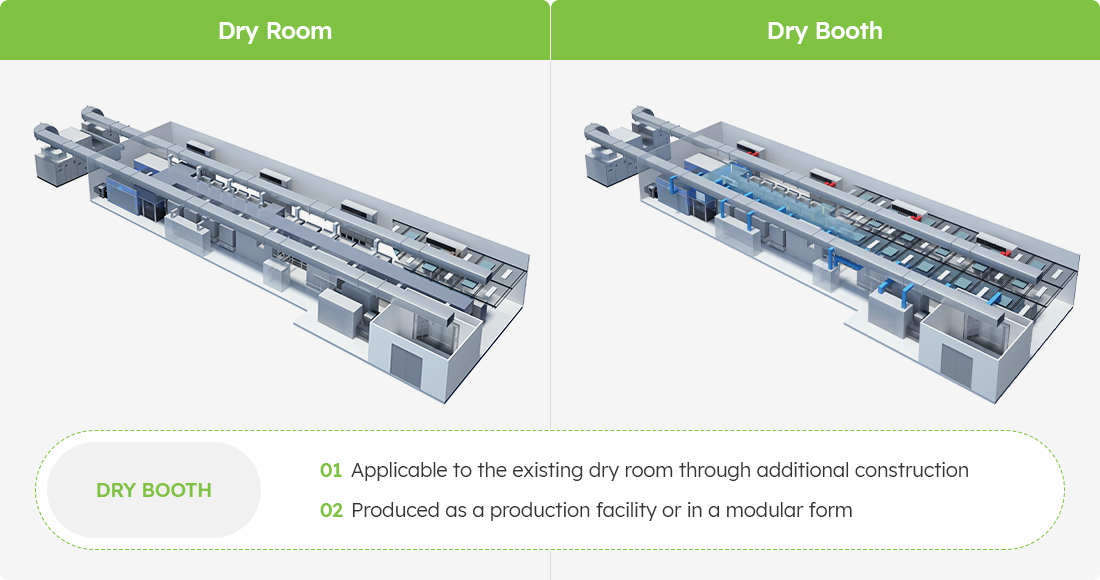

Dry Room / Dry Booth System Dry Room / Dry Booth System

- Dry Room

- Space for producing essential equipment for the manufacture of secondary batteries, such as dehumidifiers, BCUs, etc., while maintaining a constant temperature and ultra-low humidity (-40℃DP or lower)

- Dry Booth

- System that implements ultra-low dew point (-60℃DP or lower) and is optimized for future production of all-solid-state batteries by managing the production line in a separate booth form

Dehumidifier Dehumidifier

Equipment that is optimized for an ultra-low humidity (-40℃DP or lower) production environment and demonstrates excellent dehumidification performance by a dry rotor

-

01Optimal design of dehumidifying equipment based on dry room design

-

02Control of humidity and temperature depending on the unit configuration

-

03Implementation of the optimal system in any environment with simple design and easy operation

-

04Strong durability and semi-permanent characteristic with a honeycomb-structured rotor

VOCs Recovery Dehumidifier VOCs Recovery Dehumidifier

Equipment that maximizes energy savings by removing and reusing VOCs in the dehumidified air used in the dry room and handles VOCs-based chemicals generated during electrolyte injection, membrane process, and coating solution manufacturing process

-

01Energy savings of about 20% compared to outdoor air dehumidifiers

-

02Reduced facility capacity for the treatment of VOCs

-

03Patents regarding the application of a new rotor and a proprietary technology

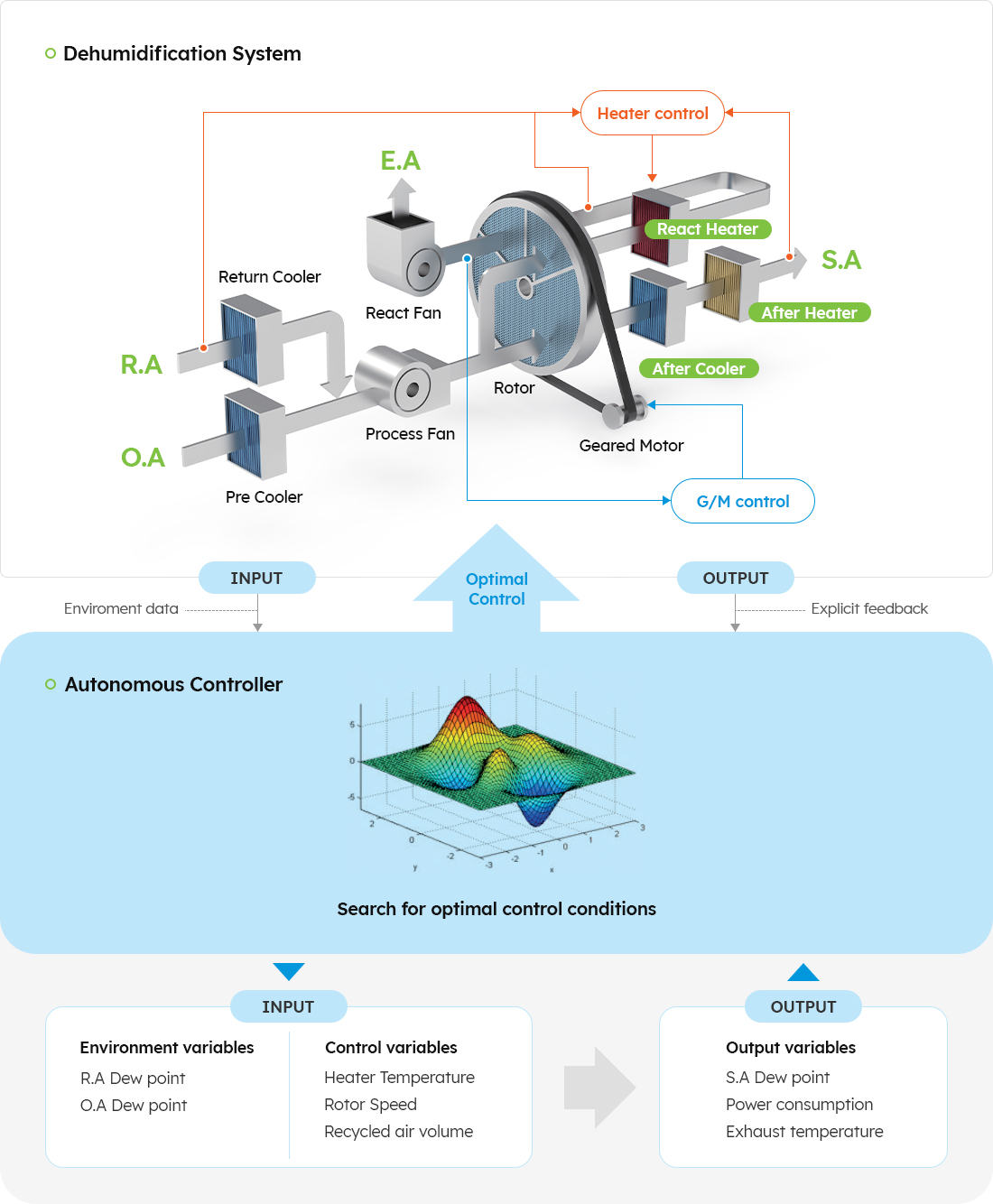

Dry Type N-Methyl-2-Pyrrolidone Recovery System Dry Type N-Methyl-2-Pyrrolidone Recovery System

System that condenses NMP solvent discharged from the cathode manufacturing process of batteries by cooling, concentrates it with a rotor, and performs the dry recovery of it with high purity

| Item | Wet NMP Recovery System | Dry NMP Treatment System |

|---|---|---|

| Processed air | Installation of large/many absorption towers Increasing the volume of NMP storage tanks | Recycling of waste heat in the production line Reducing atmospheric emissions and saving energy consumption for air-conditioning through exhaust recirculation |

| NMP recovery rate | 95% | 98% or more |

| NMP recovery purity | 80% | 95% or more |

| Atmospheric discharge concentration ratio | THC 40PPM | THC < 20PPM |

| Atmospheric discharge air volume ratio | 100% standard | 90% reduction (compared to the wet method) |

| Installation area ratio | 100% standard | 50% reduction (compared to the wet method) |

-

01Reducing the manufacturing cost of secondary batteries by recovering 95% or more of NMP, used for the manufacture of secondary batteries, with high purity and refining and recycling it

-

02Minimizing the amount of NMP discharged into the atmosphere by recovering the NMP emitted from the dryer

-

03Reducing refining energy consumption by recovering the NMP of high-purity

-

04Reducing the dehumidifier capacity required for air-conditioning during the manufacturing process by recirculating the processed air

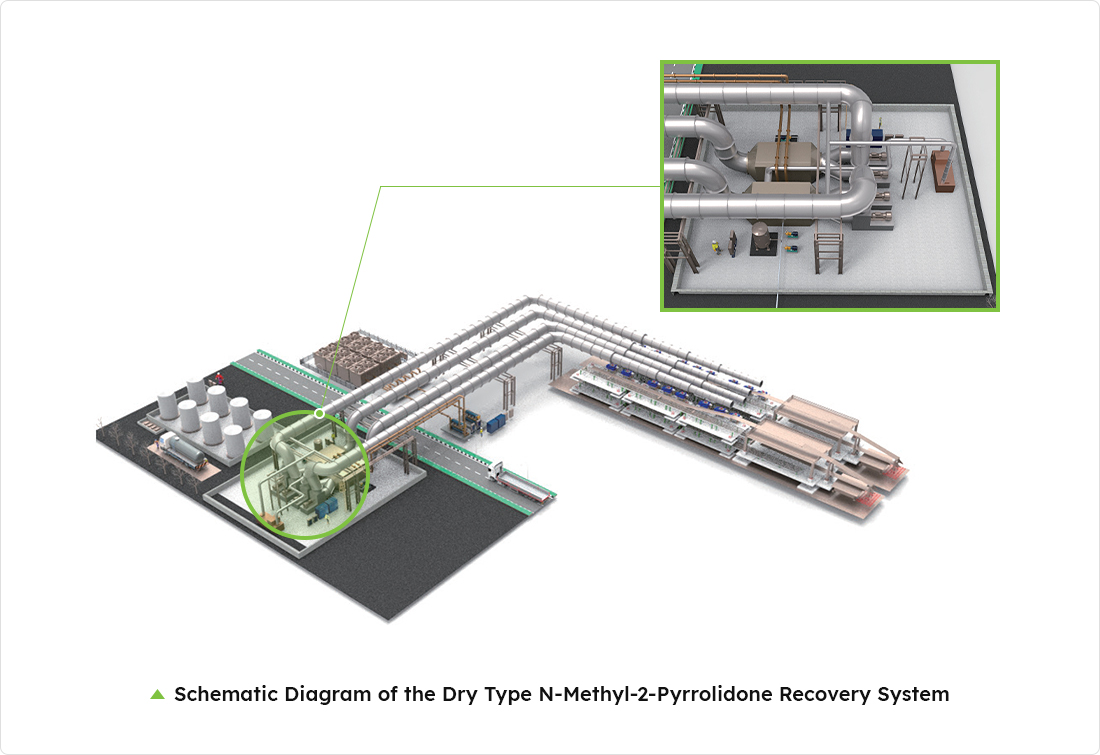

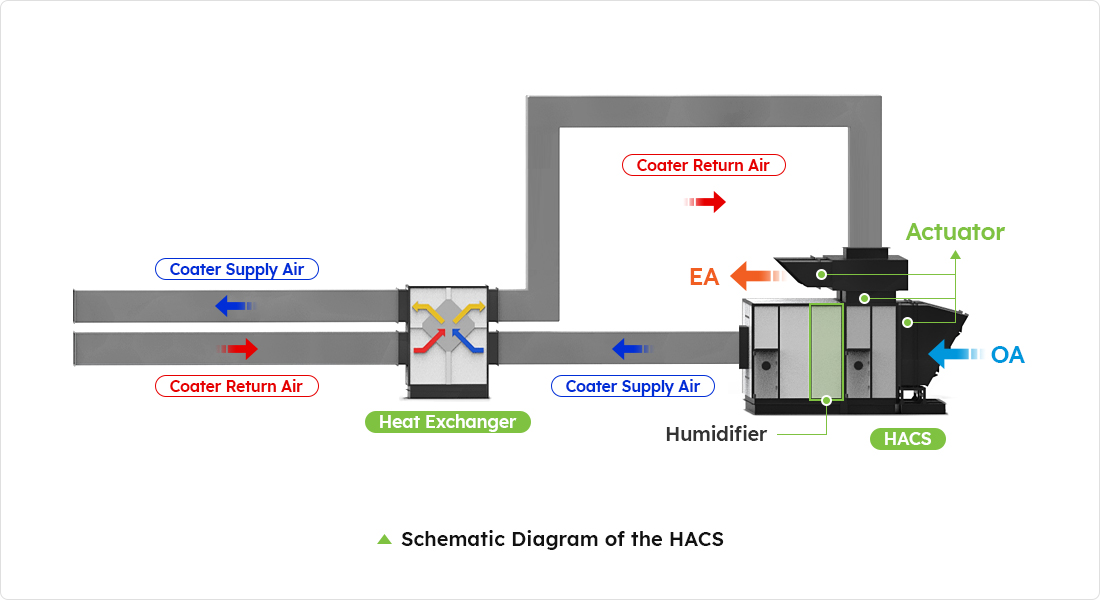

Humidity Auto Control System HACS

Equipment capable of controlling humidity by operating a humidifier to improve the production yield of secondary battery cathode coaters

-

01Shortening the over-drying time and improving the occurrence of cracks by controlling and stabilizing the spray amount of a humidifier

-

02Implementation of the optimal manufacturing environment by controlling the amount of outside and return air

By Pass Cooling Unit BCU

Cooling equipment to control sensible heat in the dry room, which can maintain cleanliness and minimize the capacity of the dry room's dehumidification air-conditioning equipment by applying an internal gun coil and applying a HEPA filter for maintaining the class

-

01Simplified structure with the sensible heat cooling method in a dry room

-

02Simplified work during on-site installation with equipment modularization

-

03Applicable to return air through the pipe cover in the equipment

-

04Reduced power consumption by applying an inverter compressor