CLEAN

ENVIRONMENT

CONTINUOUS EFFORTS

FOR A CLEANER ENVIRONMENT

Industrial Clean Room

- Clean Environment

- Industrial Clean Room

ICR, Industrial Clean Room

A high-cleanliness production space

for semiconductors and displays

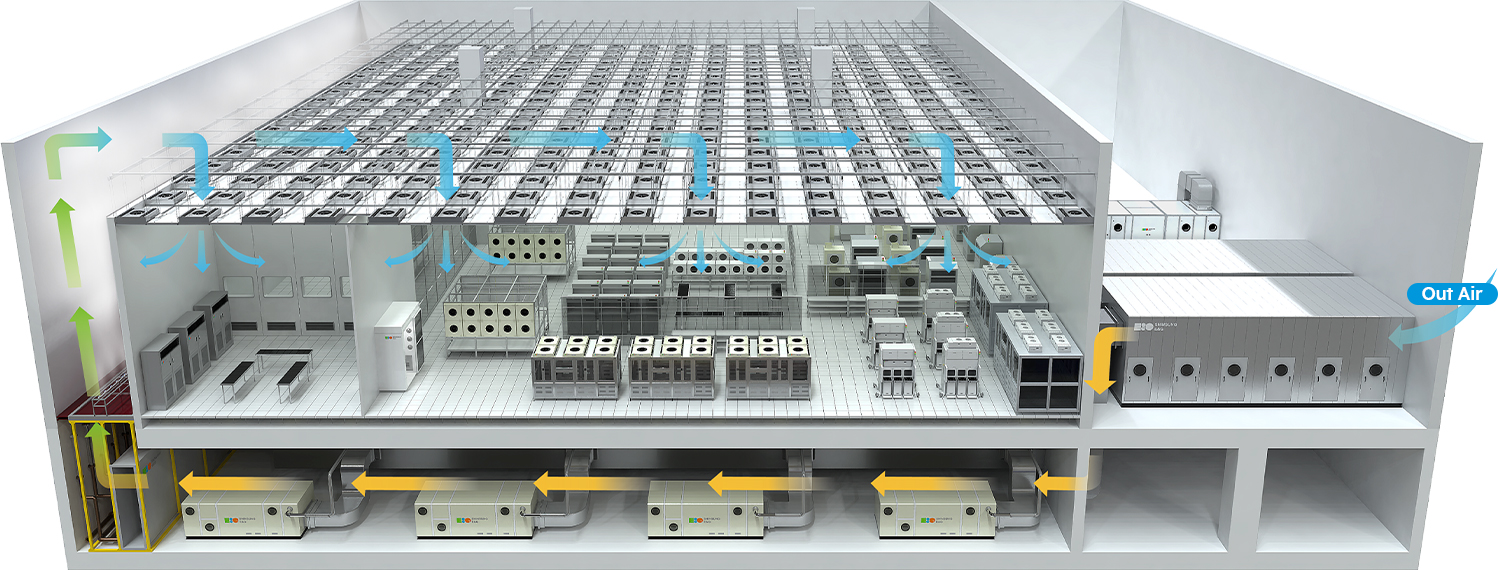

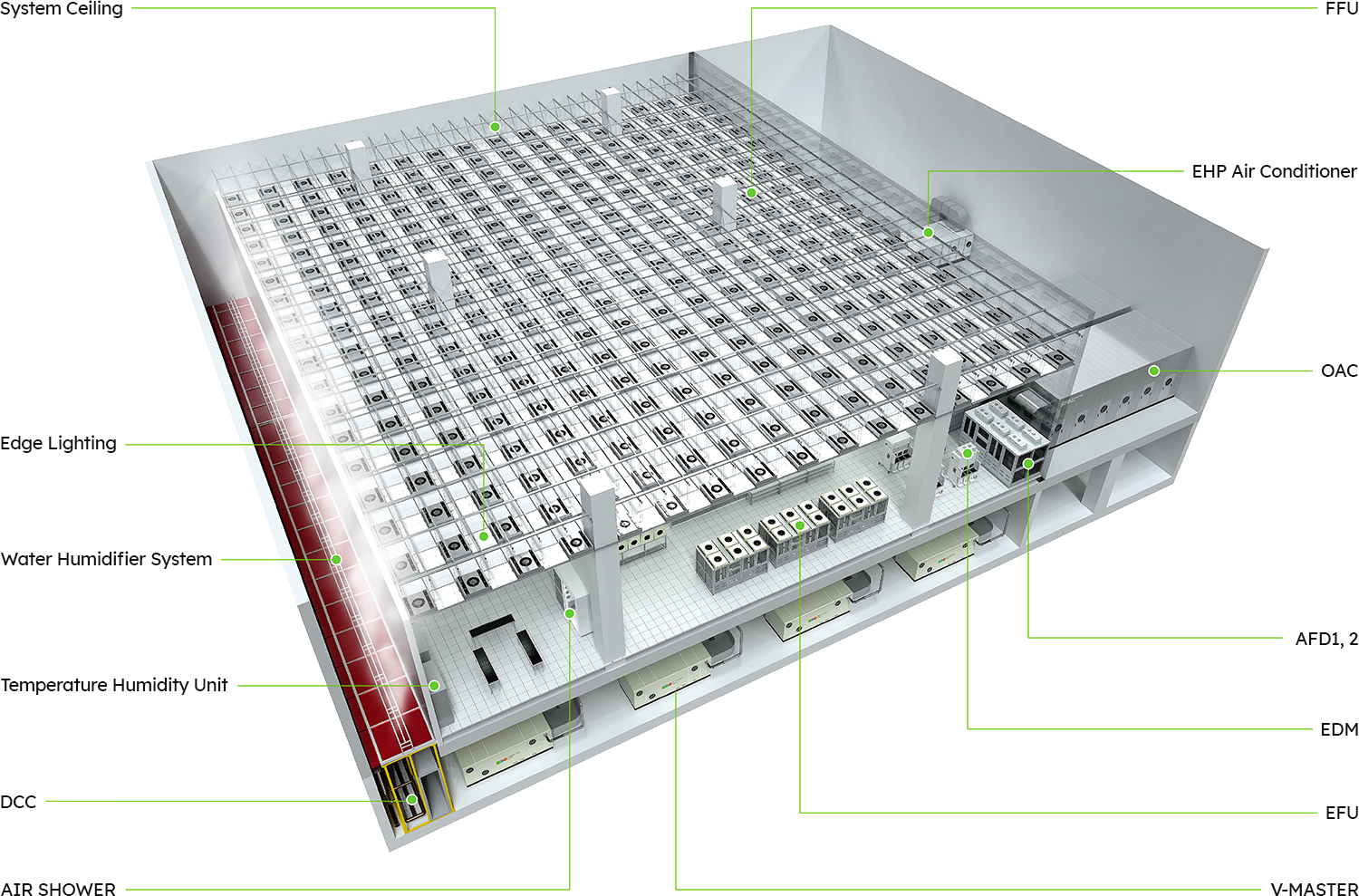

Shingsung E&G provides customers with industrial clean room solutions leading the IT industry with innovative, cutting-edge technologies. Since our founding in 1977, we have been leading the development of the clean room market for semiconductors and displays by establishing a technology research center in 1985, starting with the industrial air conditioner-centered business, while improving the quality of products and production yield by controlling the cleanliness, temperature, humidity, airflow, gaseous contaminants, etc. in the clean room. Our high-cleanliness industrial clean rooms are being applied to the semiconductor and display industries, manufacturing of precision machinery, optical devices, etc., materials supply business, etc., and, by extension, their application is expanding to various industrial fields such as secondary battery, bio, IDC, etc.

Based on the high level of trust through innovative air control technology, we are providing our customers with the best solutions for the safety of the production environment, yield improvement, and energy saving, and we are doing our best to build a customized environment for customers by establishing the temperature and humidity environment required in a clean room and continuously developing core technologies to control contaminants including AMC

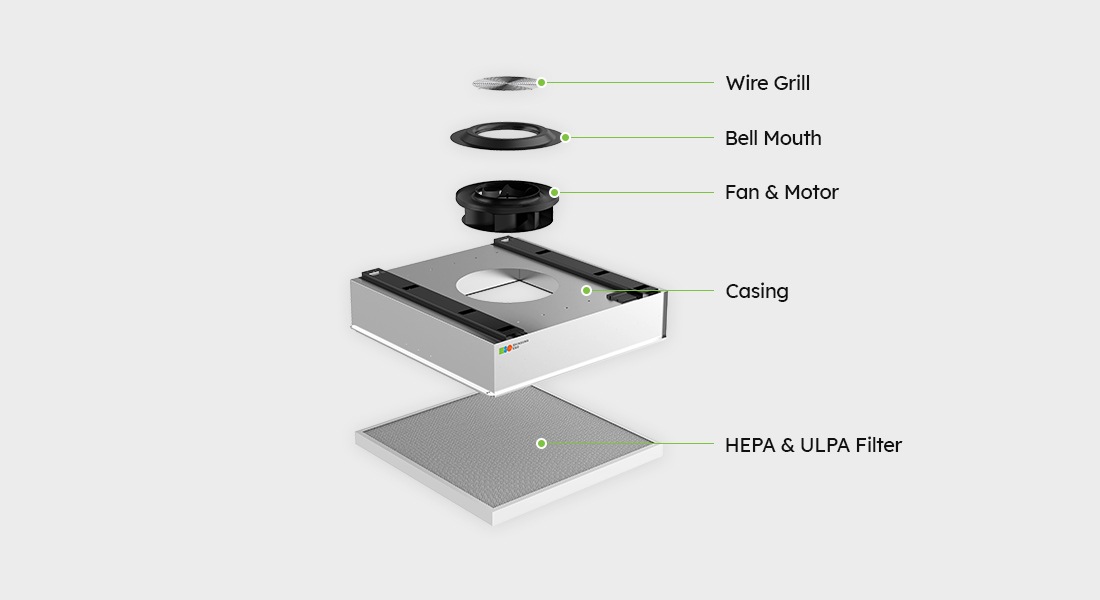

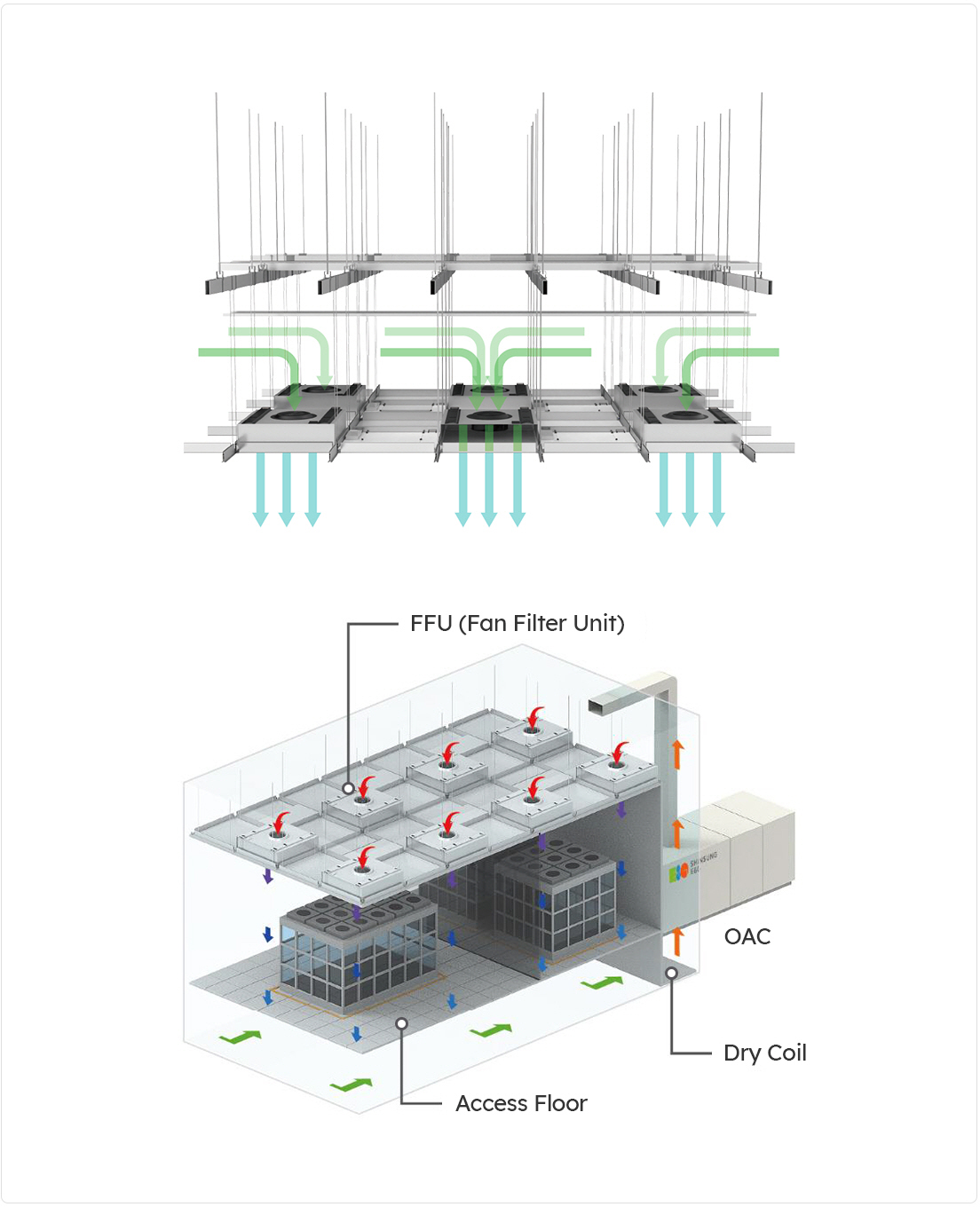

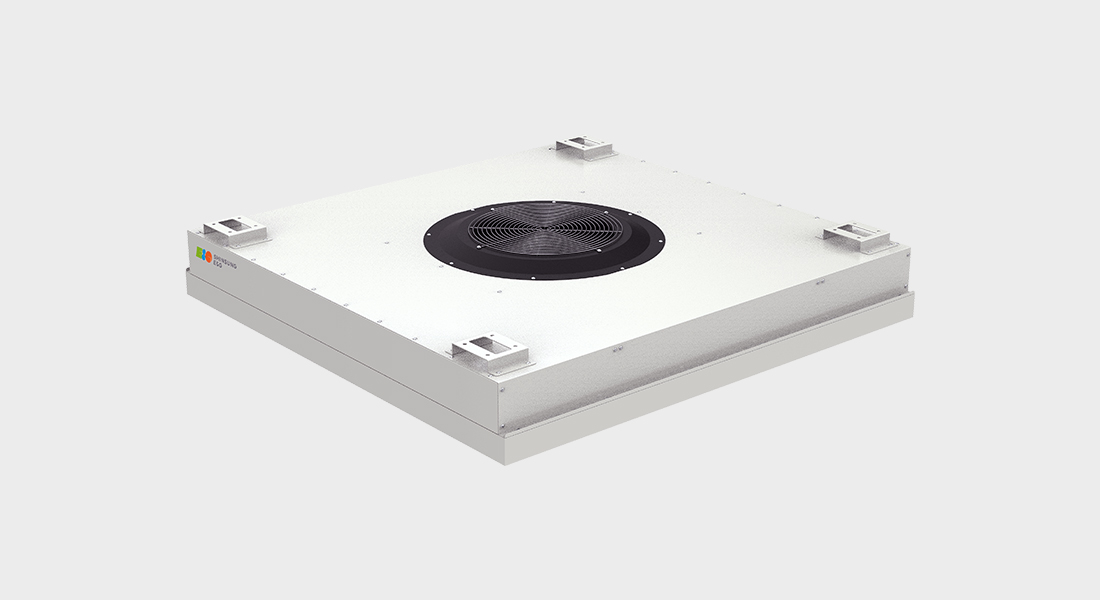

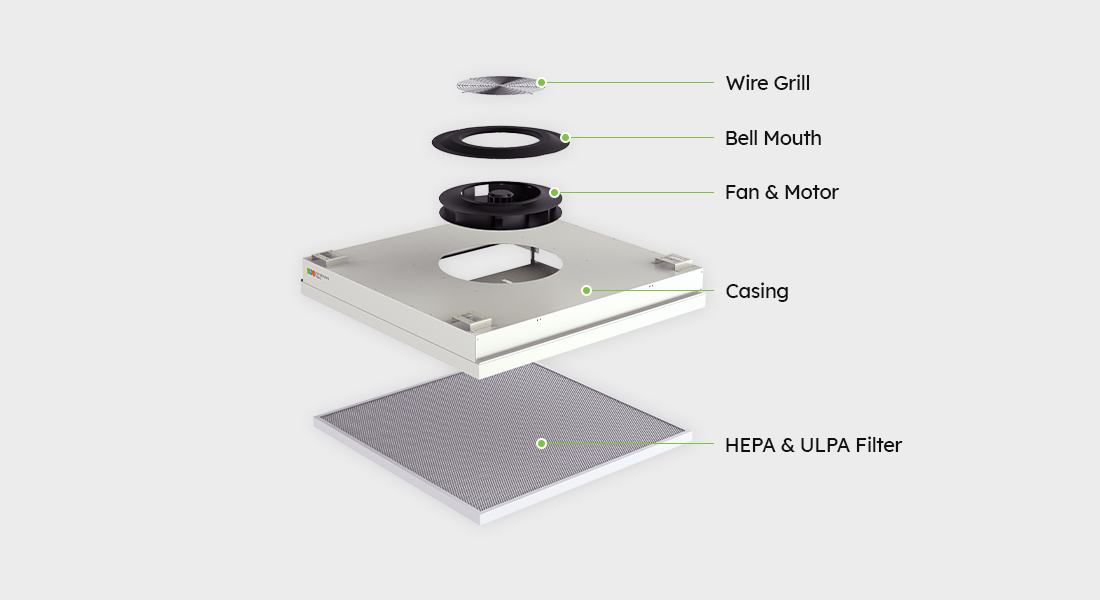

Fan Filter Unit FFU

A clean room-dedicated air cleaning system that is installed on the ceiling of the clean room to supply and circulate clean air and removes more than 99.9999% of 0.1μm particles in size

-

01Convenient change of layouts and change of cleanliness levels (Class 1 to 10,000) during renovation in clean rooms

-

02Reduced construction costs due to the separate unnecessary sound-absorbing facility as a characteristic of the low-noise type

-

03Significant energy savings due to low power consumption

-

04Convenient wind speed control and management of FFUs by the central control method

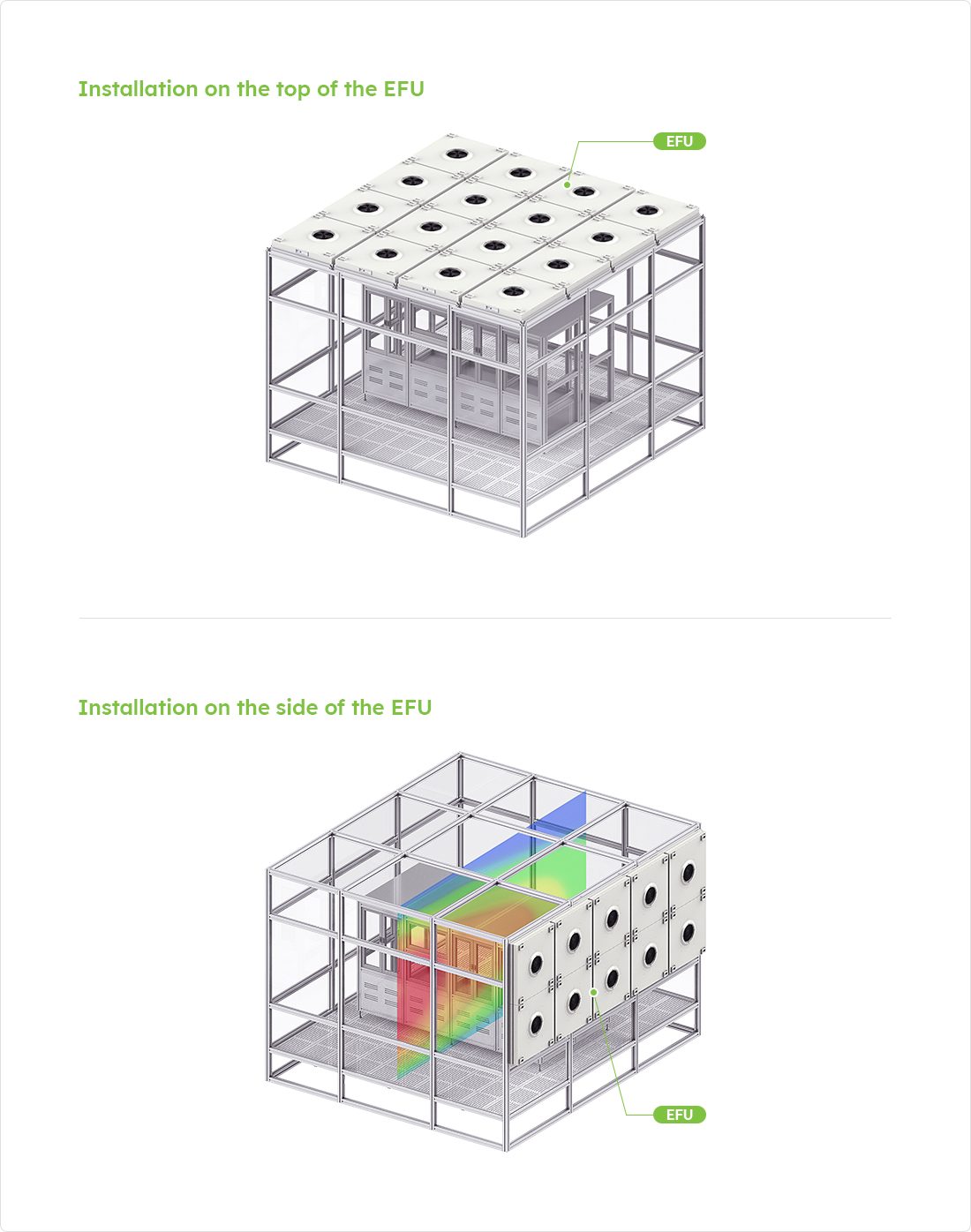

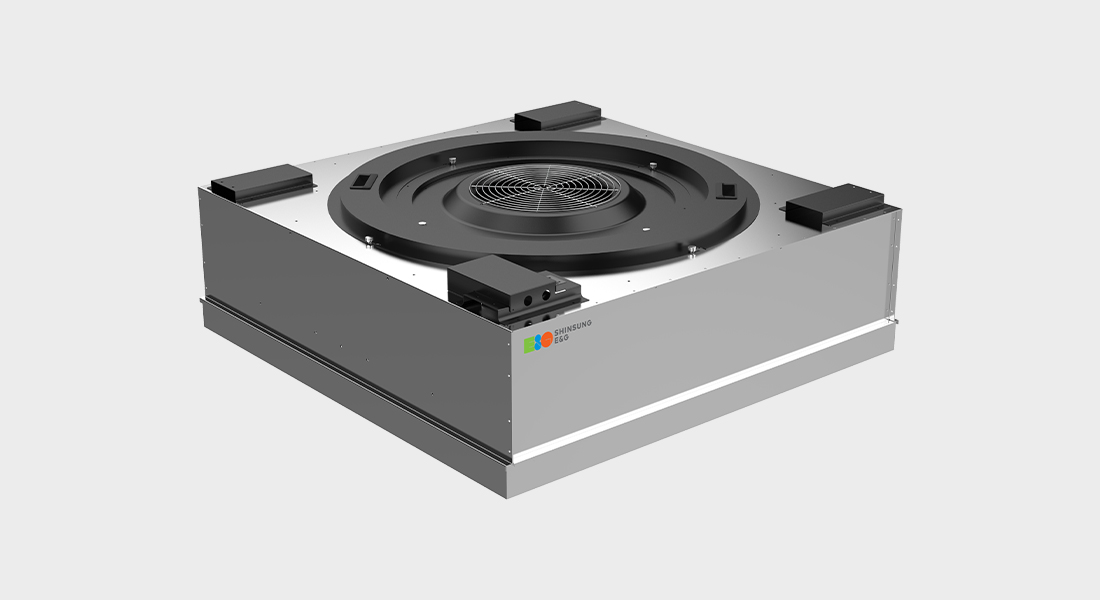

Equipment Fan Filter Unit EFU

An air cleaning system that is installed in the production facilities and mini environment in the clean room to supply clean air, maintain differential pressure, and control airflow and to remove more than 99.9999% of 0.1μm particles in size

-

01Integrated lighting/ionizer, linked SMART control (pressure, particle, airflow, etc.), and wired/wireless control

-

02Minimized energy consumption with high-efficiency fans and motors

-

03Minimized installation space constraints due to moderate height

-

04Preventing the spread of contamination and maintaining a constant state to environmental changes with the pressure balance function

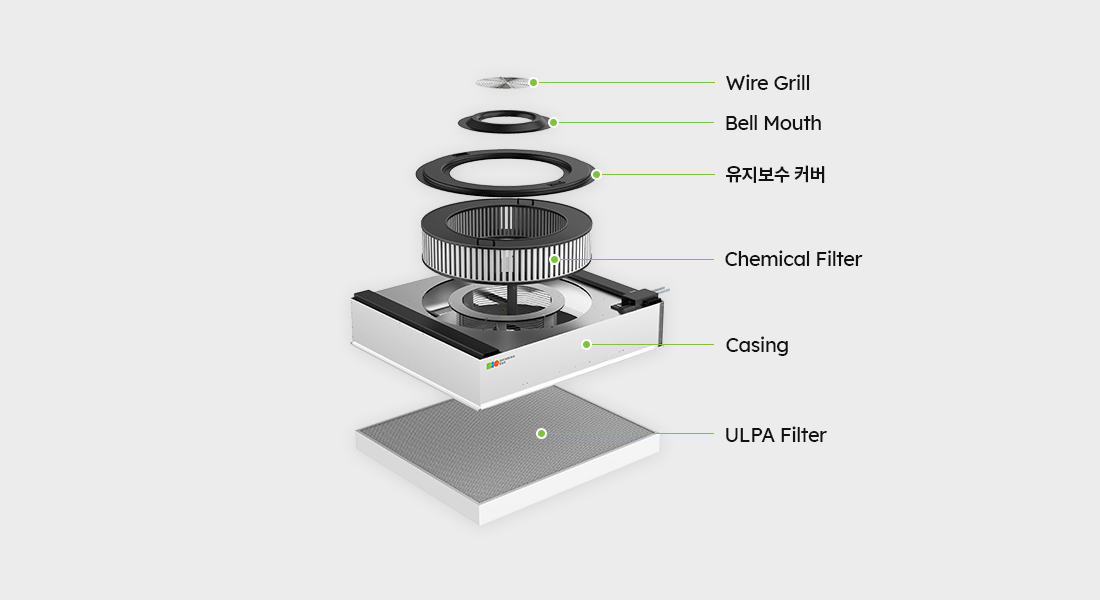

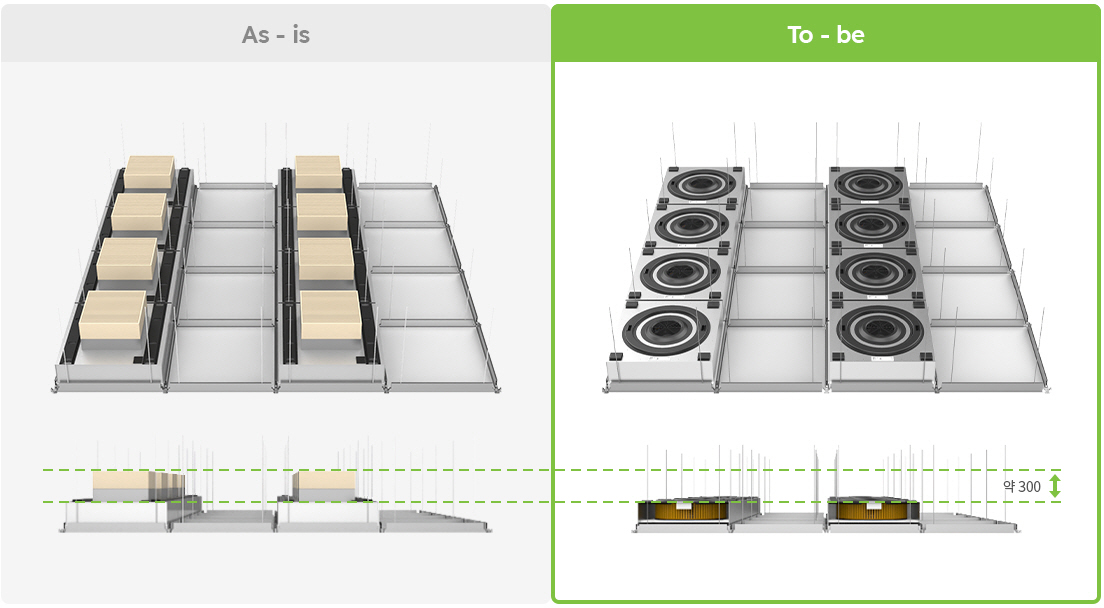

Internal Chemical Filter FFU ICF FIRST DEVELOPMENT PRODUCT

A multi-functional 3rd generation FFU that includes space efficiency, flexibility in installation/replacement, energy savings due to reduced external static pressure, and protection and additional installation of chemical filters through the chemical filters installed in the FFU

-

01Application of a suitable chemical filter for target gases such as VOCs, Acid, NH3, O3, etc.

-

02Application of an anti-backflow function (patented) and maintenance of cleanliness when replacing chemical filters

-

03Addition of functions for a specific purpose such as lighting, ionizer, keeping the wind speed constant, etc.

-

04Enhanced safety of workers by securing the upper movement line of the CR device

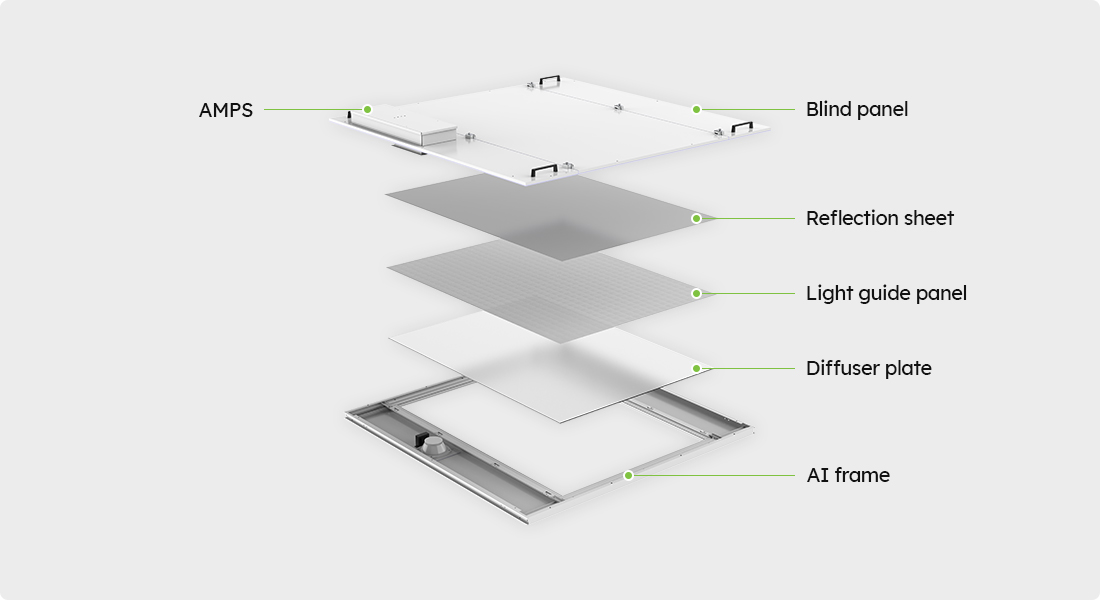

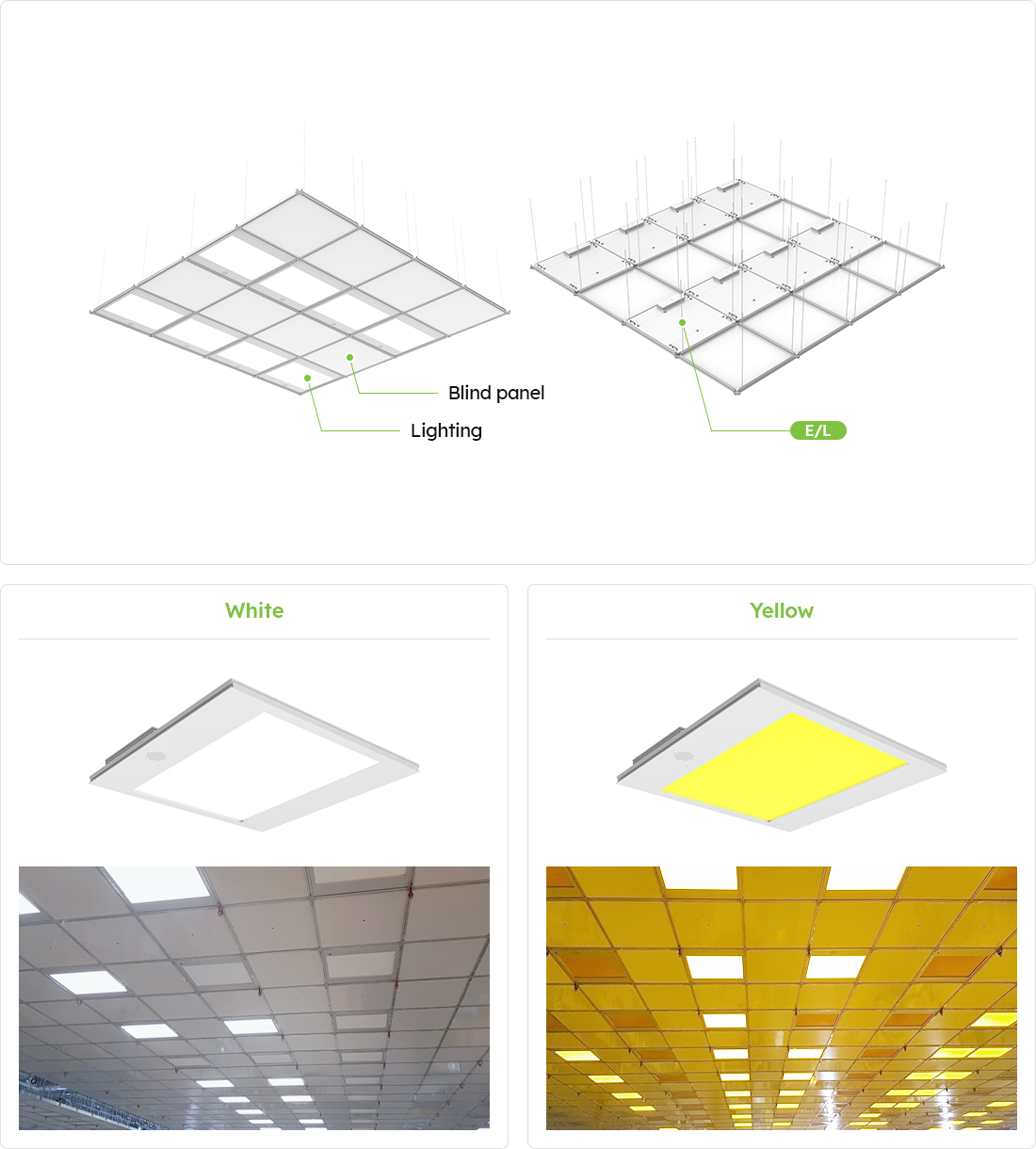

Edge Lighting E/L FIRST DEVELOPMENT PRODUCT

A clean room-specific LED edge-type lighting installed on the ceiling of a clean room

-

01Construction without interfering with other processes (replacing the existing B/P)

-

02Unnecessary high-altitude works, such as vertical lifts, etc., during maintenance

-

03Slim, lightweight, and high efficiency (over 150lm/W) due to the edge type

-

04Securing safety through the integrated blind panel

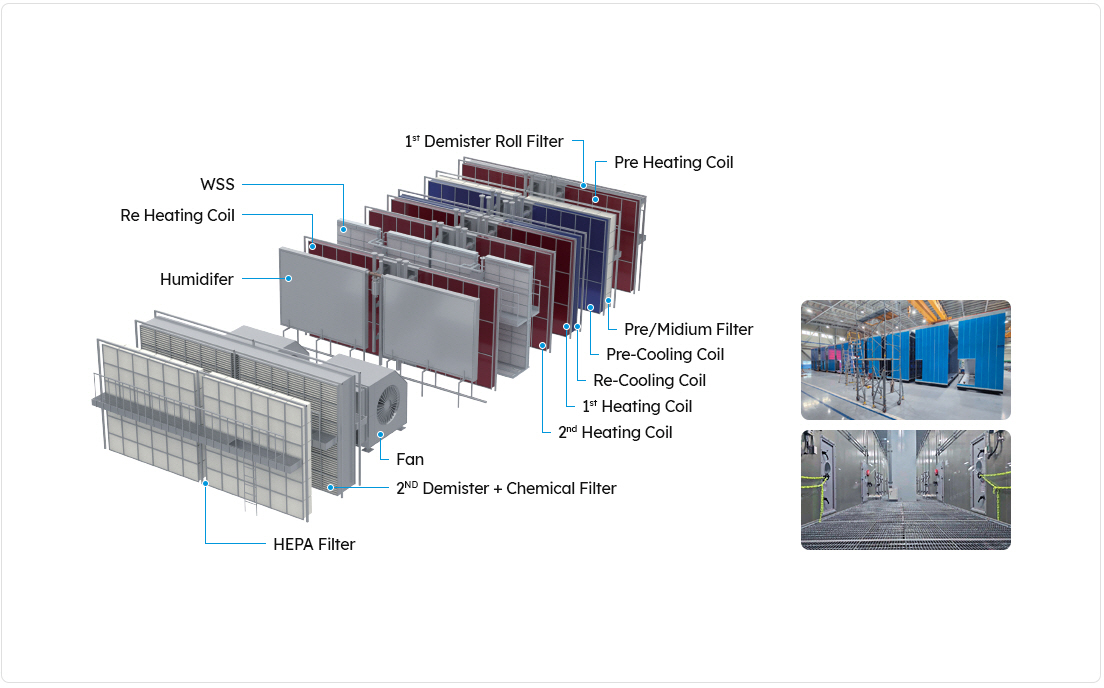

Outdoor Air Control Unit OAC

Equipment that maintains constant positive pressure and temperature and humidity in semiconductors, LCDs, and clean rooms while purifying contaminated air from outside and then supplying it.

-

01Modular and field-specific production for minimized field work

-

02Reduced installation time and minimized errors during installation

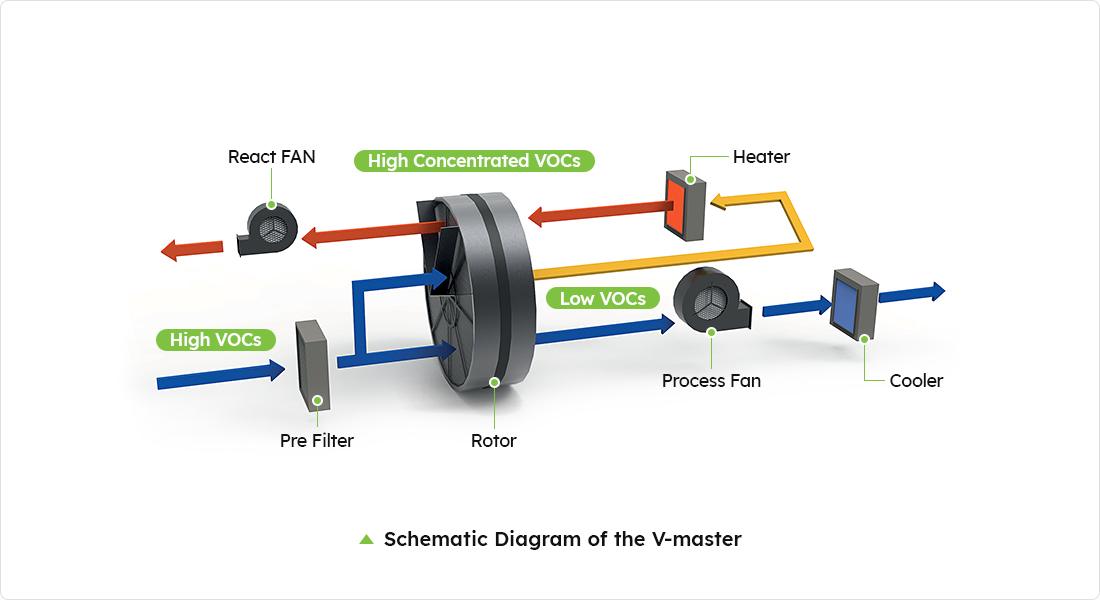

VOCs Remover V-master

Equipment that removes more than 95% of scattering VOCs, improves the production environment, and protects the health of workers through its first application to a clean room in Korea

-

01Securing the VOCs removal performance of 95% or more through continuous adsorption and desorption

-

02Minimized installation space with optimal design

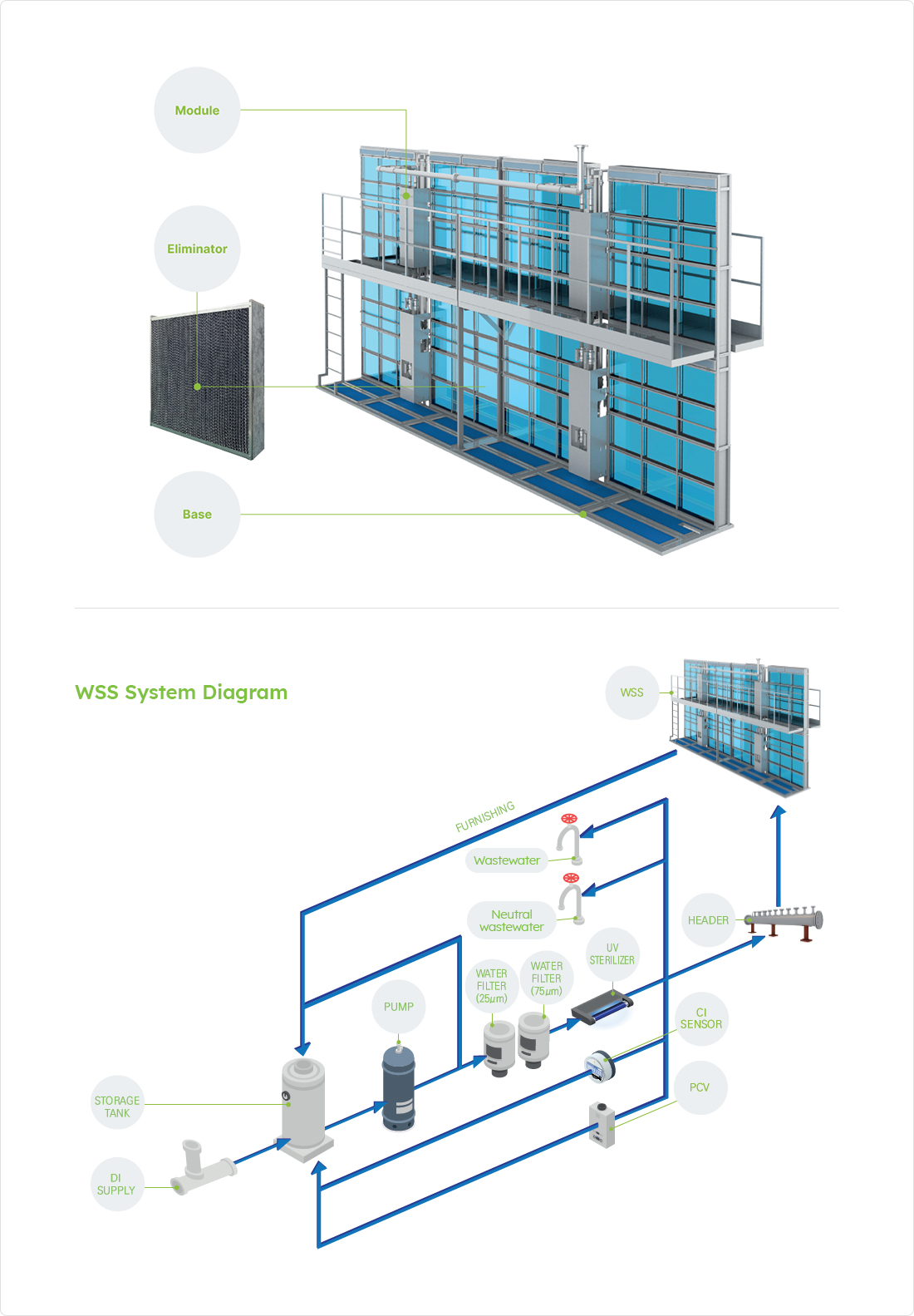

Water Showering System WSS

A system that removes ionic gas pollutants in the outside air by spraying de-lionized water

-

01Securing reliability through field verification (stable removal of ionic gas contaminants)

-

02Reduced fan motor power costs due to the use of low differential pressure and eliminator and reduced initial investment and operating costs through optimal design

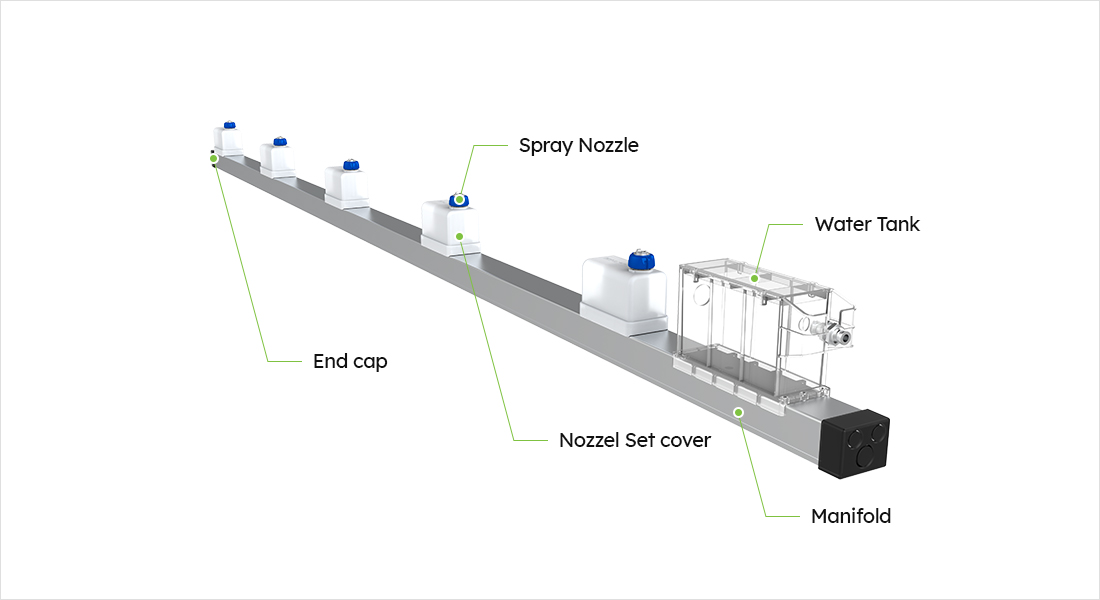

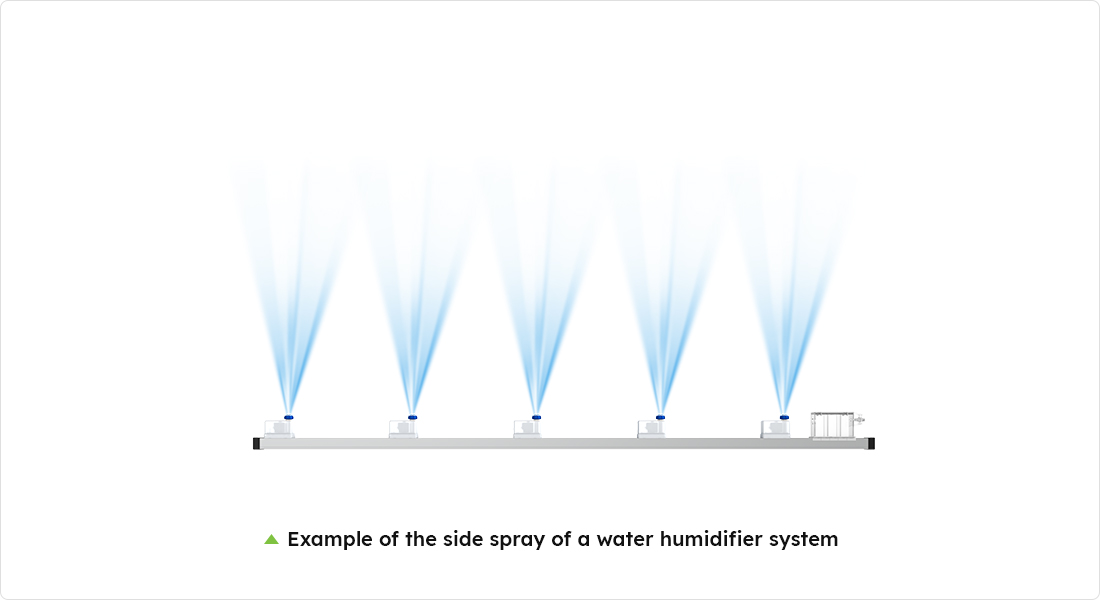

Water Humidifier System Water Humidifier System

The water humidifier system that controls humidity in a clean room, which operates on the principle of inducing water with compressed air and colliding with and vaporizing it

-

01Evaporative humidifier system that uses a nozzle for two fluids (compressed air and water)

-

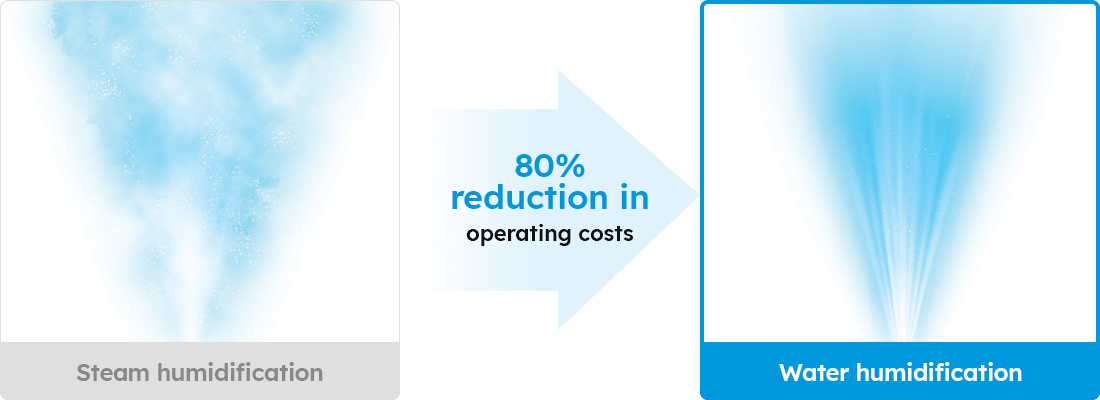

0280% reduction in operating costs compared to those of steam humidification

-

03Control of humidification amount by zone and improvement of humidification precision through individual nozzle control

-

04Reduction of the sendible heat load of a dry coil by using the latent heat of evaporated water

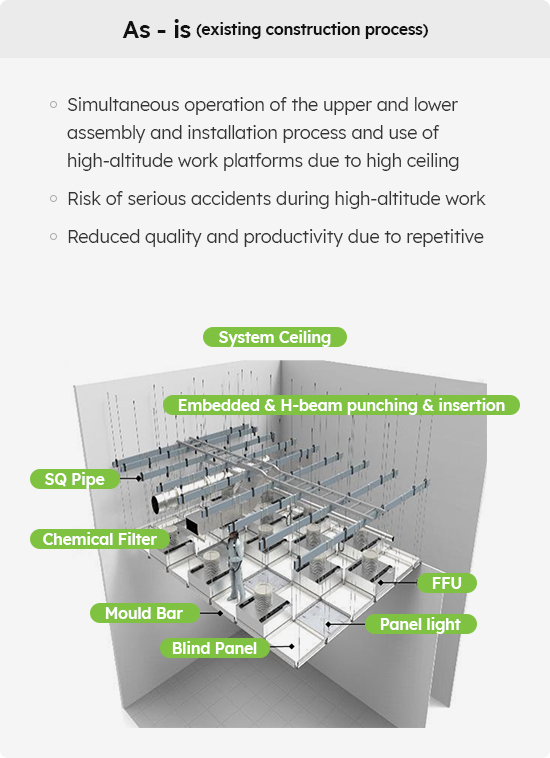

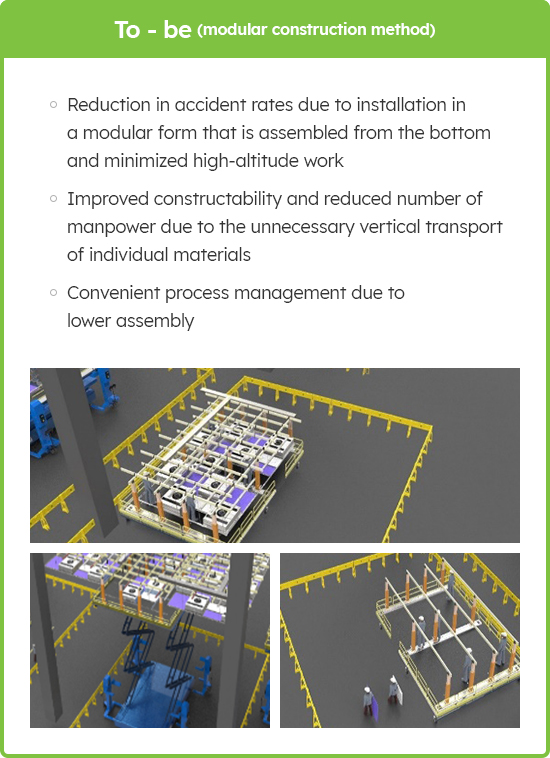

High Performance Lift HPL

No risk of safety accidents due to reduced high-altitude work and shortened construction period through the development of modularized system ceiling equipment and its construction methods with enhanced safety

- The method of lifting the modules to be installed from the bottom through 3-stage hydraulic scissor cylinder in the link plate of the HPL for the modularized system ceiling construction method

- Driven by remote control and application of 48V battery cells as power source

- Modularized system ceiling construction through the linkage of up to 20 units for the HPL